- SMS group and Tata Steel have signed a memorandum of understanding (MoU) to make arrangements for conducting a joint industrial demonstration of SMS’s innovative EASyMelt technology

- EASyMelt (Electric-Assisted Syngas smelter) technology is a cutting-edge metallurgical solution that can be implemented in existing integrated steel plants

- The objective is to cut CO2 emissions by more than 50 percent from the blast furnace’s baseline operation

- The EASyMelt concept will be implemented at Tata Steel’s blast furnace E in Jamshedpur, India.

Both parties already signed a MoU in November 2022 to jointly explore opportunities for decarbonizing steel production and have now identified EASyMelt as a key CO2 emission-reduction technology to be implemented at Tata’s steelworks. The main objective of this demonstration project will be to cut CO2 emissions in a first intermediate step by more than 50 percent from the blast furnace’s baseline operation.

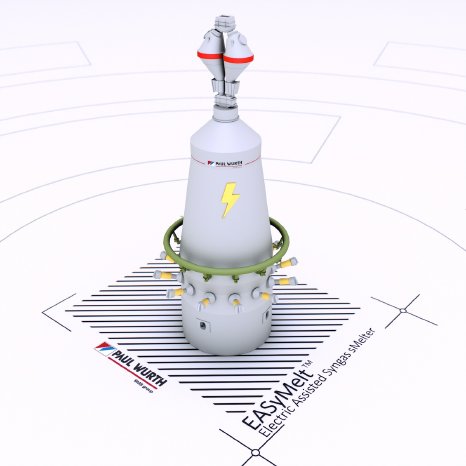

The EASyMelt (Electric-Assisted Syngas smelter) technology, developed by SMS group company Paul Wurth, is a cutting-edge metallurgical solution that can be implemented in existing integrated steel plants and used to accelerate decarbonization. The core of the technology utilizes blast furnace top gas recycling for syngas production by reforming the coke oven gas. The resulting syngas is then injected at both shaft and tuyere level, whereby a plasma torch system is used to further heat the gas injected at tuyere level.

“We are very proud to team up with a major steel producer like Tata Steel, and look forward to our future interactions as well as the possibility of achieving a first joint reference for our EASyMelt technology,” said Burkhard Dahmen, CEO of SMS group. “This will represent a significant milestone for the decarbonization of existing blast furnace plants worldwide and thus also a significant milestone in the global transformation of steel making.”

T. V. Narendran, CEO and Managing Director of Tata Steel, said: “Tata Steel is actively looking for solutions to facilitate the transition to green steel production, and thus contribute to a sustainable future. Further, India being the second largest steel producer in the world also places a huge responsibility on large manufacturers like Tata Steel to lead the country’s decarbonization journey. We are delighted to reaffirm our partnership with SMS group and intend to take this association ahead with a deeper collaboration to access better technologies and processes to reduce our carbon footprint in a meaningful and consistent way.”