Key Facts

- RAMPF specializes in customized gasket contract manufacturing services that enhance efficiency and longevity of components in the automotive, electronics, energy technology, household appliance, lighting, and medical technology industries.

- By leveraging its global expertise in reactive plastic systems and state-of-the-art automated mixing and dispensing technology, the company delivers exceptional value and performance.

- RAMPF’s advanced production facilities in Wixom, MI, and Suwanee, GA, are ideal for customers with irregular production schedules or small batch sizes that do not justify investing in dedicated equipment.

- Reactive plastic systems based on polyurethane and silicone, ranging from liquid to highly thixotropic gasketing solutions.

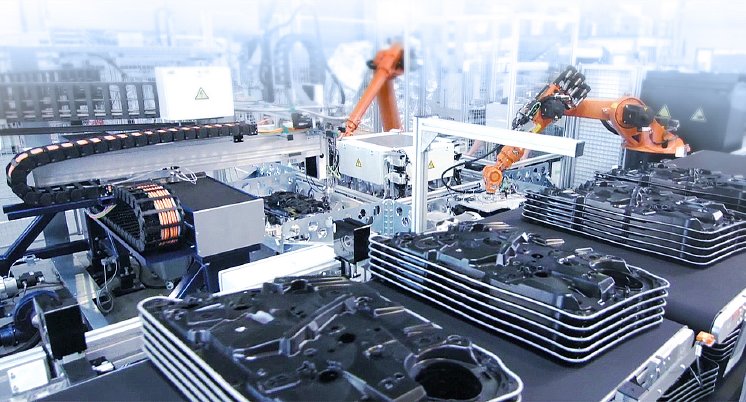

- Automated mixing and dispensing technology for ultrafast, ultraprecise, and cost-efficient manufacturing processes.

RAMPF’s liquid to highly thixotropic two-component foam gaskets and elastomer seals based on polyurethane (RAKU® PUR) and silicone (RAKU® SIL) deliver high-performance sealing with outstanding quality and user-friendly handling.

Using FIPFG (Formed-In-Place Foam Gasket) and FIPG (Formed-In-Place Gasket) technologies, the sealing systems are applied directly onto components via dispensing systems, eliminating the need for inserted or adhesive seals. The materials expand in place, cure quickly, and significantly reduce cycle times while improving processing efficiency.

Mixing & Dispensing Systems – Ultrafast. Ultraprecise. Cost Efficient.

RAMPF’s high-performance, low-maintenance mixing and dispensing systems ensure precise, efficient processing of reactive plastics. Gaskets are applied directly to components with rapid curing, reduced cycle times, and maximized throughput. Key benefits include:

- Dynamic mixing technology for consistent reactivity across a broad viscosity range

- Precisely coordinated material handling, preparation, and dispensing for flawless application

- Advanced automation with robotic integration, component handling, image recognition, and sensor technology

With state-of-the-art facilities in Wixom, MI, and Suwanee, GA, and a cross-industry experienced team, RAMPF provides highly flexible manufacturing support with a deep understanding of both materials and processing.

Gordon Winter, Operations Manager at RAMPF Group, Inc. – “Our top-tier facilities are ideal for customers with intermittent production needs or low volumes that do not warrant equipment investment. RAMPF also handles high-volume contract manufacturing – either at customer sites or in-house.”

Visit RAMPF at Plastec East in New York, May 20 to 22 – Booth 510!