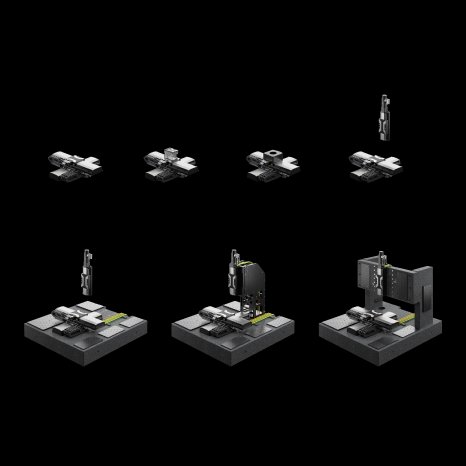

At its core, the X-417 is a high-load XY system built on precision linear stages, offering travel ranges from 102 mm to 407 mm. Depending on space and process requirements, a Z axis can be integrated to create a fully configured three-axis system, either mounted directly on the XY platform or supported by a dedicated bracket. Alternatively, a precision rotation stage can be used as Z axis for applications requiring rotational positioning. The system is easy to set up, minimizing integration effort and time to operation. Support for functional safety enables deployment in environments with elevated safety standards, including automated production lines and laser applications.

Three Performance Classes for Precision and Throughput

To meet varying precision and throughput requirements, PI offers the X-417 system in three preconfigured performance classes. Each variant features precisely aligned components and includes the G-901 ACS high-performance controller with comprehensive software support. The system can be extended with granite base plates and aluminum or granite axis brackets.

High-Performance Motion Control and Easy Integration

The X-417 platform delivers exceptional contouring performance, enhanced by ServoBoost™ technology. It provides increased throughput and precision, making it ideal for demanding motion tasks. Powered by the ACS motion controller, the system supports PLC environments and EtherCAT communication, as well as easy laser integration. Comprehensive measurement and mapping data support process stability and precision.

Application Versatility for Advanced Manufacturing

The X-417 system is engineered for high-precision tasks, including laser micromachining (drilling, cutting, and structuring), ultrashort pulse laser processing, and electronics manufacturing. The system also enables Galvo scanner integration. Further use cases range from inspection and test systems to the precise processing of ceramics, glass, and diamond.

Ready to Run: Fast Deployment and Expert Support

Each X-417 system is delivered fully preconfigured with cabling, alignment, adjustments, calibration, and detailed test reports to ensure immediate and reliable performance. PI provides on-site engineering and application support to tailor the system to individual technical requirements. Thanks to short lead times across all configurations, companies benefit from faster project timelines: whether they need high-precision, complex machining, or cost-efficient production solutions.