PICMA® multilayer bending actuators are characterized by a large travel. A low transversal change in length of the active layers is converted into a large bending displacement in a direction vertical to the contraction. In this way, displacements of up to two millimeters can be achieved with response times in the millisecond range.

The high resonant frequency of the multilayer bending actuators offers the best prerequisites for highly dynamic applications.

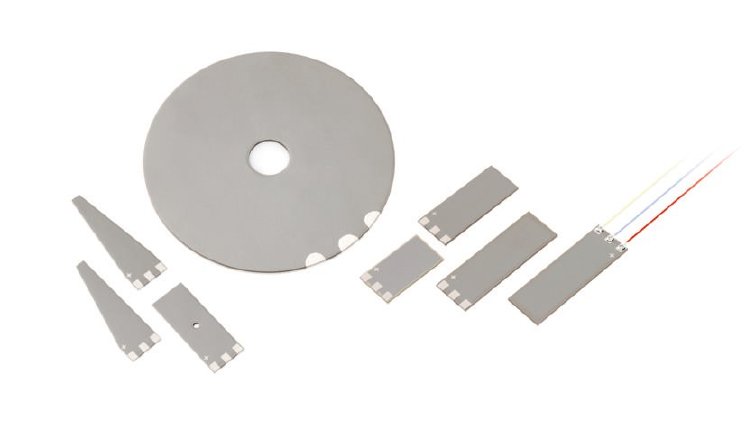

The manufacturing process makes PICMA® Benders possible in almost any shape and size. In addition to different geometries, PI Ceramic offers customized versions. The height of the active layers is variable, for example, starting at a minimum height of 15 μm, so that even operating voltages of only 10 V can be used. A one-sided displacement is possible if the actuators are attached to a substrate, this allows a higher stiffness and a larger displacement in one direction than is possible with bidirectional bending elements. Linearity and repeatability in position-controlled operation can be improved by using position sensors. Multilayer contracting plates can also be placed on the customer's own substrate (metal, silicon).

Their reliability and low operating voltage makes PICMA® bending actuators ideal for dosing and pumping applications, for optical beam deflection, and when minimally dimensioned, for use in portable devices.

Since 1992, PI Ceramic (PIC) has been developing and manufacturing piezo ceramic materials and components for standard and OEM solutions: Piezo components, ultrasonic transducers, actuators, and system solutions. The PICMA® multilayer actuator technology, which received an award for its reliability, is one of many innovations of PIC. PI Ceramic, a subsidiary of PI (Physik Instrumente), is located in the city of Lederhose, Thuringia, Germany.