The robust plasma cutting unit Plasma Cutter has earnt an excellent reputation for cutting, gouging, and marking of Steel, Stainless Steel and Aluminium or Copper in plate processing because of its powerful performance and flexibility. With six operating modes, the easily managed Plasma Cutter is outstandingly suitable for economical hand or machine cutting and ensures high productivity in plate processing.

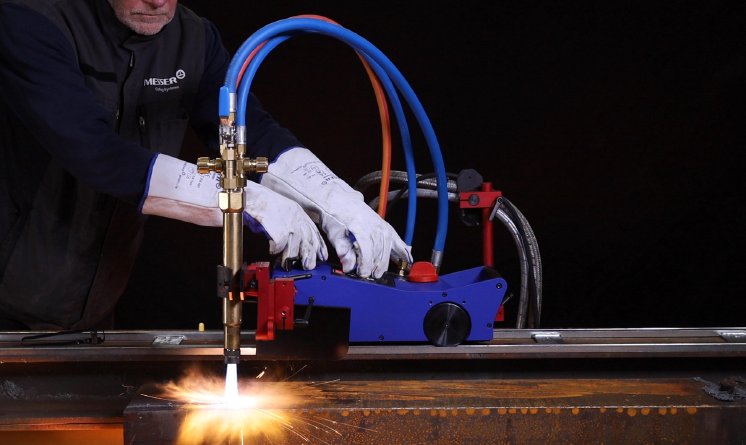

Joachim Pauly, Product Manager Oxyfuel Global at Messer Cutting Systems: “The two portable cutting machines ensure flexibility and productivity in plate processing for the user.”

S.A.T.: So no more fires!

In future the new level of safety for oxyfuel hand cutting torches is called S.A.T. The patented system is quasi a “leakage finder” which protects the working environment from leakage and thus greatly increases the safety of workplaces where hand cutting is carried out: because, the longer the hose, the greater its exposure to damage – whether from flying sparks, sharp edged objects, or other dangers at the workplace. With conventional torch systems such hose leakage usually remains unnoticed as the behaviour of the torch does not alter so the user has no indication of the leak. S.A.T., consisting of the S.A.T. valve and hand cutting torch, solves this problem, in that the flame on the torch is extinguished if the hose is damaged. Additionally the gas supply from the S.A.T. valve is stopped automatically. Setting the flame becomes completely unnecessary with the S.A.T. system.

“In this way, S.A.T. not only ensures a significant improvement in workplace safety, but also saves time and ensures more operating comfort as the flame no longer needs to be adjusted” adds Joachim Pauly.

New strengths with Hydrogen as fuel gas

Fuel gasses such as Acetylene and Propane are based on Carbon, so there is an acute need, also in cutting technology, for alternatives or for solutions to reduce the CO2 footprint: The solution is HyCut. The system – from gas through to application technology – has been specially developed for the use of Hydrogen as fuel gas and meets modern demands for quality, productivity, and economy in oxyfuel equipment.

Jörg Mosser, CEO Messer Cutting Systems Europa: “Protecting the climate, safe, high performance, economical – on the path to decarbonising the economy, Hydrogen as a fuel gas for oxyfuel equipment can play an important role. The joint development between Messer and Messer Cutting Systems, HyCut is the new high performance and sustainable alternative to conventional oxyfuel equipment technology. Our tests have shown that the use of HyCut gasses significantly reduce emissions of CO2, Nitrogen oxides and dust.

This not only contributes to environmental protection but also improves health protection at the workplace. What is more, our HyCut gasses in combination with our further developed oxyfuel equipment open up measurable cost advantages.”