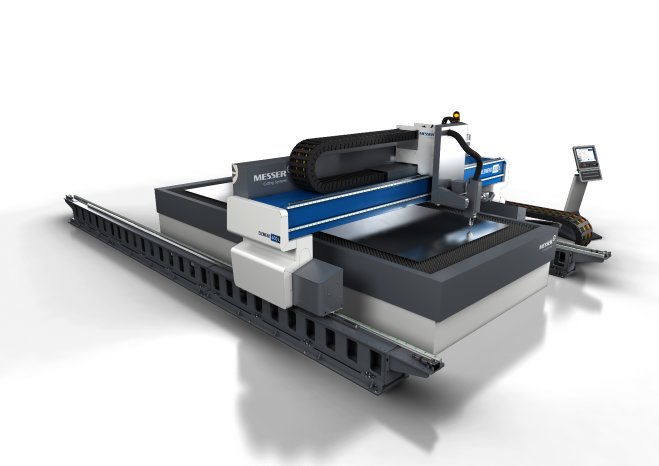

The laser machine ELEMENT L combines simultaneous hole piercing and faster cuts with laser precision cutting, all in one machine. It cuts Mild Steel, Stainless Steel and Aluminium with O2 and N2 as well the optimum automatic gas mixing unit. With positioning speeds up to 140 m/min (combination X-/Y axes) and a high acceleration, the unit scores with high speeds and, thanks to linear guides in the X and Y axes, with outstanding positioning accuracy.

The productivity has been significantly increased using high-speed lifters and modern process optimisation techniques. Independent tools, driven by servomotors, offer a range of processing possibilities. The CNC control has been developed to increase the efficiency significantly, eliminate unnecessary information and to make production operations more transparent.

Set-up times can be reduced by the automatic positioning of multiple tools from the part program or the optionally available control.

Plasma and Laser combined

Multiple tools can be integrated in the ELEMENT L. Both the number of torches and their space can be programmed. The user can combine the newest laser technology (maximum two stations) with advanced plasma technology here.

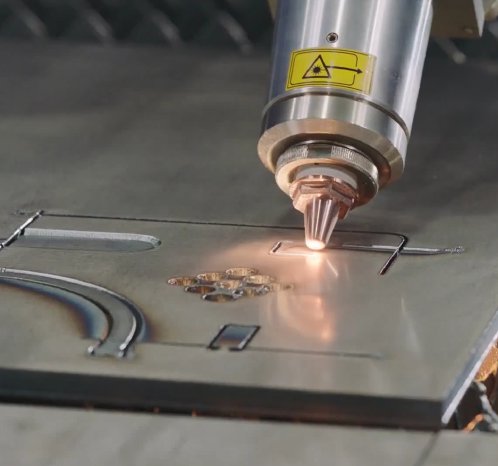

Ingo Staudinger, Product Manager, Laser and Material Handling: “Highlight of the Element 400 L is the bevel cutting head Bevel-U, specially developed for the laser process. With its design, the Bevel-U is perfectly suited to produce precise and consistently accurate bevel parts – a great advantage in weld preparation for automated robot welding.” Bevels between -50° and +50° are possible in workpieces, as are different edge shapes for a subsequent welding process. The bevel angle can be continuously, steplessly varied during the laser cutting process. A magnetic collision protection for the cutting head is also included in the design of the Bevel-U as is a manual operating console for all drives, to be able to carry out set-up work directly on the machine.

Solutions for more Automation

Ingo Staudinger: “Bearing in mind the lack of skilled craftspeople and the urge for higher productivity, quality and sustainability, plate processers are increasingly seeking automated solutions, which, amongst other things, make a low manning operation possible. There is an enormous potential in this area which we can tap into for the user.”

With the newest developments in laser cutting technology, Messer Cutting Systems has created outstanding prerequisites for an automated production. Often it is the little things which give the decisive advantage, for example with handling: To be able to handle a part better after processing, the Messer cutting technology makes it possible to leave micro bridges between the cut part and the scrap frame. So each part does not have to be handled individually, but the plate can be simply removed as one piece by the loading/unloading system or a shuttle table. This significantly reduces non-productive times. The bridges are so fine that they can be easily parted from the frame later.

“One feature for the automation of the ELEMENT L is the nozzle changer “Laser Nozzle Control” (LNC). It automates the set-up quickly and reliably and thus ensures maximum processing quality and productivity – for every material, every thickness and every process – and that with no manual intervention”, states Ingo Staudinger. The LNC ensures reliably high cut quality and shortens set-up times. Machine idle time is prevented, and the plate processor gets reliable planning and optimisation.

High precision in the production process

The plate position is decisive for an accurate cut. There are always deviations here. With the ELEMENT L that is no problem. Before cutting, the actual orientation of the plate is determined with the cutting nozzle sensing and the CNC program is rotated correspondingly – manually from the operating console or fully automatically from the program. This drastically reduces the effort when placing the plate on the machine and helps to achieve optimum plate utilisation.

Just as important for the processing quality of the production process is a uniform motion of the machine. The ELEMENT L is equipped with a helical geared drive and precision linear guides. These provide the basis for fluid movements. Powerful AC servomotors ensure fast acceleration of the cutting tool in and around holes and corners. Thus, an outstanding cut quality is achieved.

Marking included

Additionally, different marking tools can be integrated in the ELEMENT L: to produce non-permanent labels such as layout lines or a simple part identification on the plate, Messer Cutting Systems offer an Inkjet marker. For permanent marking a stylus marker is available for the ELEMENT L.

Safety first

“High protection of person and machine is the first commandment for us in the design of a machine”, affirms Ingo Staudinger. “The functional safety technology of the integrated, internationally certified, TwinSAFE systems not only prevents damage to the machine and minimises down-time but, above all, gives optimum protection to the operator.”

Digitalisation in the production

The ELEMENT L is complemented by the powerful software solutions from Messer Cutting Systems. They ensure maximum transparency in production operations, production planning and control. To smooth the way further for a continuous networking, the Global Connect can process production orders directly and achieve maximum productivity, especially in combination with the products of the OmniFab family. That the operator interface is clearly and simply structured helps the user to call and use all features with no problems.