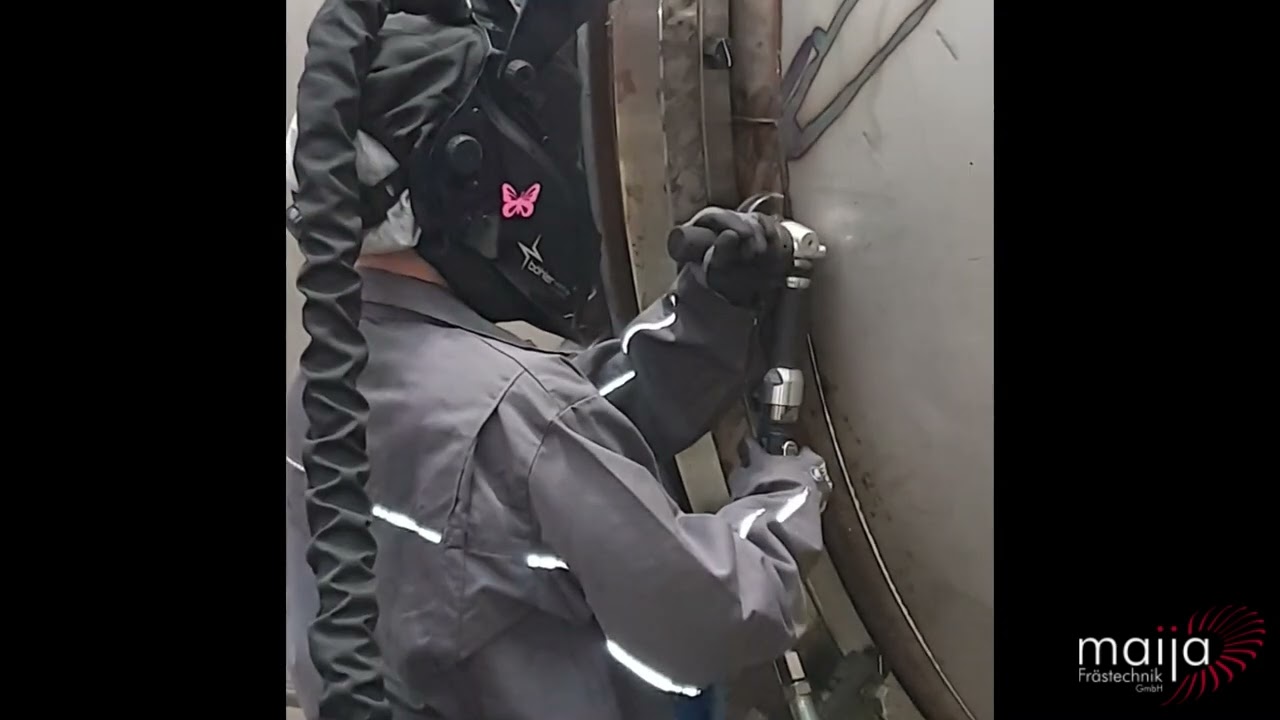

Once positioned, the worker only has to keep the machine with the MAIJA DoubleWorker on track to achieve perfect weld seam preparation on the rotating body. In this specific application, the unique positioning also makes it possible to integrate or implement the process as a (partially) automated process.

The demonstration shows machining on a refuse collection vehicle, where no chrome-nickel dust may be produced when machining the material (1.4301). This problem is avoided by using MAIJA milling discs with the appropriate, approved machine. The machining process produces chips, not dust.