A special field of application for MAIJA milling discs is work on highly heated components. To demonstrate its use, a rail was heated so that it had a temperature of 430°C during machining. As an example, welds were leveled during the demonstration, but it is just as possible to open welds to correct any welding defects that may be present, prepare the weld to be metallically bright, and weld again. To carry out this work with a grinding/roughing wheel, the component would first have to be cooled down and, if necessary, then heated up again. With the MAIJA milling discs, this work can be carried out directly while the part is still hot, thus saving a great deal of time. Due to the location-independent use of the milling discs, this is possible wherever it is needed, without having to transport the component to be machined.

MAIJA milling discs in automation and with heated components

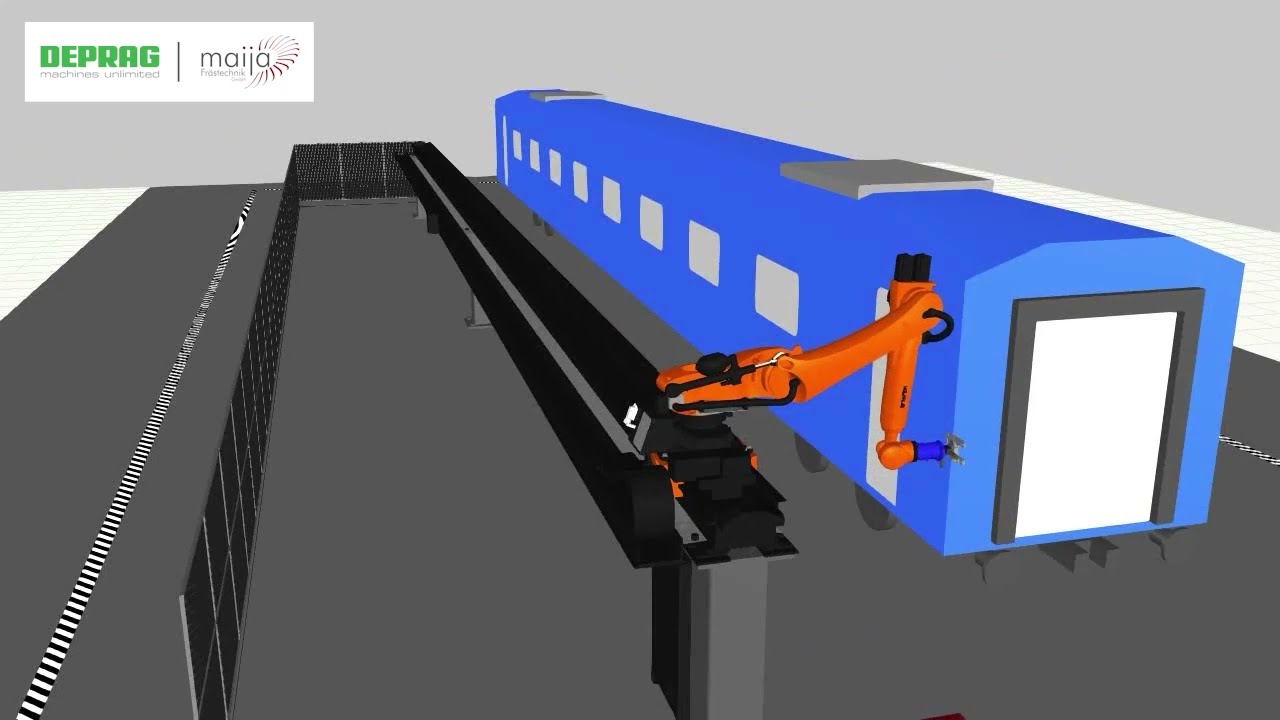

Using the MAIJA milling discs in automation and with highly heated components

A special field of application for MAIJA milling discs is work on highly heated components. To demonstrate its use, a rail was heated so that it had a temperature of 430°C during machining. As an example, welds were leveled during the demonstration, but it is just as possible to open welds to correct any welding defects that may be present, prepare the weld to be metallically bright, and weld again. To carry out this work with a grinding/roughing wheel, the component would first have to be cooled down and, if necessary, then heated up again. With the MAIJA milling discs, this work can be carried out directly while the part is still hot, thus saving a great deal of time. Due to the location-independent use of the milling discs, this is possible wherever it is needed, without having to transport the component to be machined.