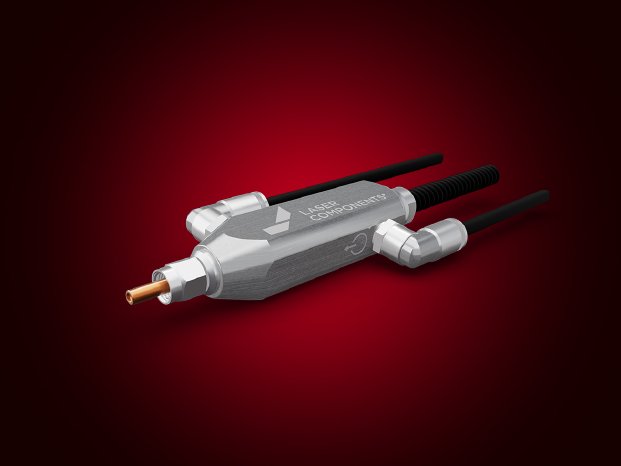

Even in high-power applications, the advanced water-cooling system of the active version allows for optimum heat dissipation. Each hour, some 30 liters of distilled water flow around a heat sink made of stainless steel or copper and maintain the operating temperature at a constant level of up to 35 °C. For laser powers from 60 W (@ 200µm) up to 130W and more, LASER COMPONENTS also offers its customers a more cost-effective version without water cooling.

In both versions, the manufacturer's own ModeStrip technology prevents the formation of disruptive cladding modes and thus prevents the fibers from overheating and burning out.