We will be exhibiting these laser-heating systems along with their processed samples at Photonix 2021 (21st International Laser & Photonics Expo), Japan’s largest optoelectronics and laser technology exhibition. It will be held at the Makuhari Messe convention center (Mihama-ku, Chiba-city, Japan) over three days from Wednesday December 8 to Friday December 10, 2021.

Product overview

The product lineup includes a total of five laser-heating systems. Each system consists of an LD irradiation light source, a laser transmission optical fiber, and a beam irradiation unit.

All are designed and combined to exhibit optimum performance for specific laser thermal processing applications and tasks.

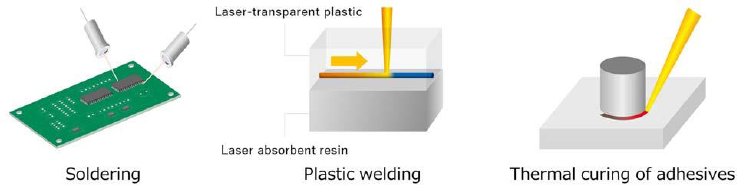

We design, develop, manufacture and market LD irradiation light sources for a broad range of thermal processing applications including laser soldering, plastic welding, adhesive thermal curing, drying, and hardening. Our unique optical design technology ensures our LD irradiation light sources emit laser beams with uniform intensity distribution on the irradiated surface to allow high-quality processing with no uneven or irregular heating.

Another unique feature is the use of a single optical fiber for both processing and measurement, which gives accurate thermal information at the laser irradiation point to ensure accurate control of processing quality.

Optimal conditions for laser thermal processing differ depending on the particular application. Up until now, users needed to select a light source and its options (optical fiber and beam irradiation unit) from more than 300 combinations. However, thanks to the technical knowledge and expertise we built through more than 10 years of experience, users can now easily select the optimal laser-heating system for their particular laserprocessing application. These applications include for example laser soldering of microcomponents for smartphones, plastic welding of automobile parts, and thermal curing of adhesives to bond dissimilar materials.

Additionally, the pre-assembled configuration of these laser-heating systems make them available to users at a low cost. In fact, it achieves higher efficiency and minimizes the environmental load compared to conventional heating methods such as soldering irons, ultrasonic welders, and heating furnaces. Therefore, the production using these laserheating systems will help lower carbon emissions for a more sustainable society.

The customization is possible in order to meet particular user needs such as different laser spot diameters and so on.

We will continue to design, develop and market laser-heating systems with higher power for an ever-expanding applications including laser sintering of metal nanoparticle inks.

Development background

Expectations for laser thermal processing has been increasing as a promising technique due to higher output power and lower-cost LDs that have recently become available.

However, it is still a new technique and not yet widely used because of concerns about processing reliability and quality control. To deal with this issue, we have designed, developed, manufactured, and sold LD irradiation light sources that emit uniform laser beams while simultaneously monitoring and controlling processing quality with extremely high accuracy. Nevertheless, there was still the challenge of selecting the ideal light source and its options for a specific application. Our new lineup of laser-heating systems will solve this challenge.