The company’s hygienic machine concept is based on essential structural features such as closed, smooth surfaces without dead spaces, fully drainable systems, and hygienically optimized weld seams. Rounded transitions and optional heated components help prevent product residues, reduce the risk of microbial growth, and ensure complete system drainage.

Regulatory Compliance and Risk-Based Validation

All GREIF-VELOX food-grade systems use product-contacting materials that comply with EU Regulation 1935/2004 and, optionally, with relevant FDA standards. Design implementation incorporates a HACCP-based validation process to identify and eliminate potential contamination risks at the earliest design stage.

Technical Solutions for Critical Hygiene Points

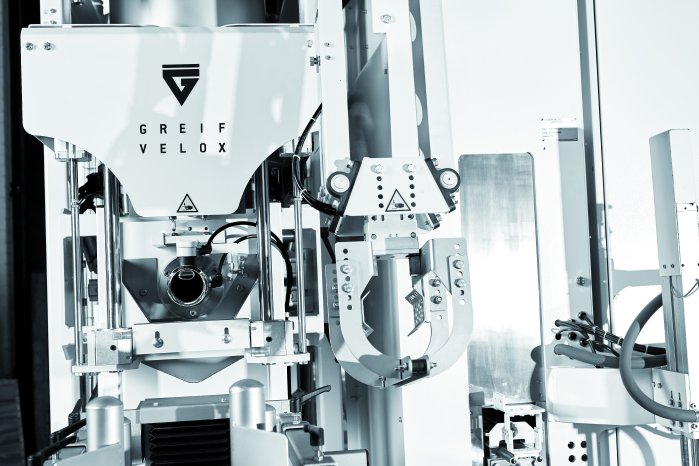

This approach is exemplified in the Brutto Pneumatic Packer (BVP) from GREIF-VELOX: an integrated suction system reduces dust emissions and cross-contamination risks, while the patented “Waffle Welding” ultrasonic sealing method with dual sealing lines significantly improves packaging integrity. The ValvoDetect system automatically verifies valve positioning, contributing to final packaging safety.

Integrated wet-cleaning systems enable documented cleaning processes - an essential feature for allergen-sensitive applications and GMP-compliant workflows. Tool-free component access also enhances system inspection and maintenance.

Tangible Advantages for Food Manufacturers

Strict implementation of hygienic design principles offers food producers measurable benefits:

- Reduced cleaning times and less downtime

- Lower total cost of ownership due to minimized quality-related costs

- Improved traceability through digital documentation

- Increased food safety by preventing contamination

- Dust-free and transport-secure packaging

- Flexible adaptation to sector-specific requirements

You can find more information and a whitepaper on the topic on the GREIF-VELOX website: https://www.greif-velox.com/en/hygienic-design-in-the-food-industry