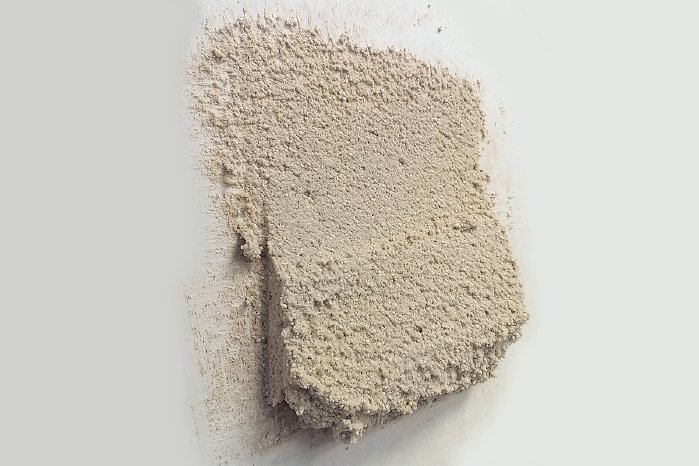

Mineral-based Aerogel thermal insulation renders are ultra-light, water-repellent, open to diffusion and achieve high thermal insulation even with small layer thicknesses.

The high-performance products are particularly suitable for the interior and exterior renovation of historic buildings. Due to the thin application layer, the characteristics of the building remain largely unchanged. The innovative building material is also used for rendering masonry in new buildings. According to their material properties, the insulating renders are also classified as "non-combustible, smoke-development free, non dripping". This means that they can also be used for facades, where previously only mineral wool-based insulating materials could be used due to increased fire protection requirements.

Formulation development

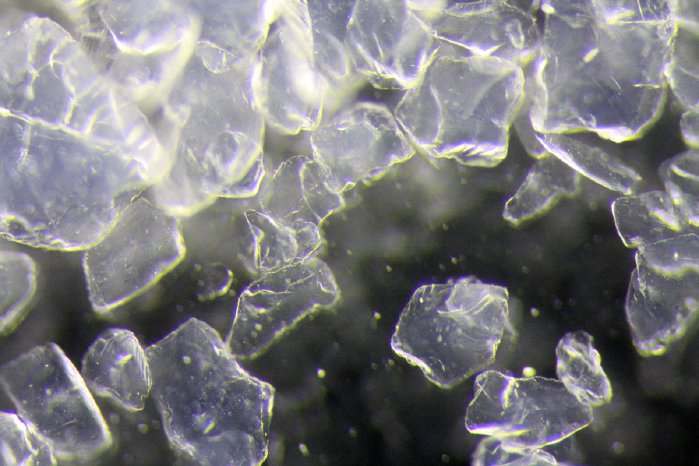

Poraver® and Aerogel were combined for the development of a purely mineral thermal insulation render in order to combine the advantages of both lightweight aggregates.

Cabot Aerogel GmbH supplied Aerogel in the form of 0.01 to 4 millimetre granules for the insulation render. Poraver® was added to the render as a mineral aggregate with a grain size of 1-2 mm. Various proportions of Aerogel and Poraver® were tested. After the tests, it could be determined that the compressive strength and processing properties had improved significantly with the addition of Poraver®. The most economical and practicable formulation has a thermal conductivity of 0.037 W/mK with a dry bulk density of 199 kg/m³.

More information and the guideline formulation as PDF

Request our aerogel thermal insulation render formulation with Poraver® without obligation by simply contacting us via our contact form.

Find out more about other applications with Poraver®.