52 AutomationML members are committed to an open industry standard

The goal of AutomationML e.V., founded in 2009, is the distribution and further development of AutomationML as an open, free industry standard for the company-wide exchange of data for the planning of manufacturing systems. The data format is neutral and should offer all options in the future: consistent programming, operation and data output of digital tools.

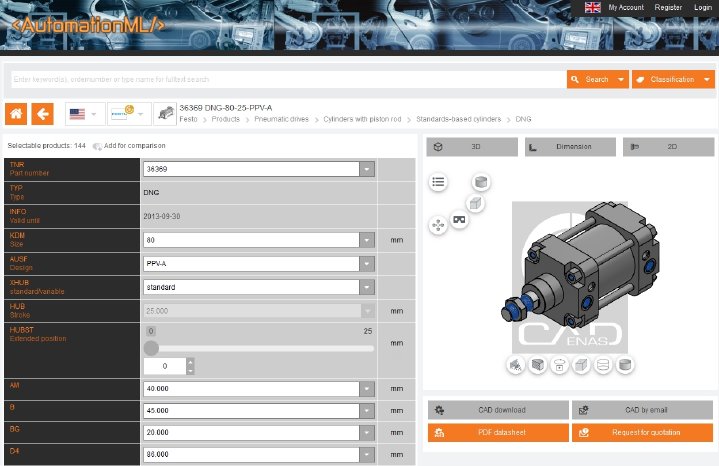

Numerous active AutomationML members such as Festo, ABB, Balluff, PHOENIX CONTACT, Schneider Electric, Sick, etc. are already making their intelligent engineering data available on the 3D CAD download portal based on the CADENAS technology.

Thus, component manufacturers are taking the decisive step towards digital product transformation

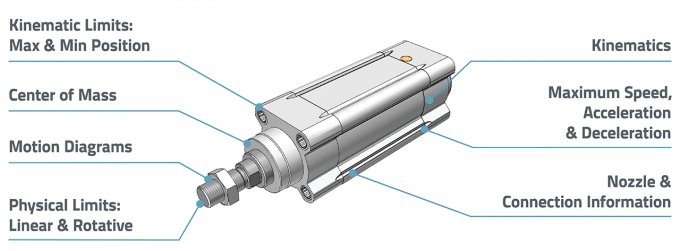

The geometry of a component alone is not sufficient for a design. With an Electronic Product Catalog based on the eCATALOGsolutions technology powered by CADENAS, the 3D CAD models receive intelligent functions that go beyond mere geometry. They use the semantic structuring of the corresponding data developed by AutomationML e.V. within the framework of its standardization for the modeling of automation components and which follows the rules of the representation of an administration shell of Industry 4.0. Thus component manufacturers are well-equipped for the age of Industry 4.0. The intelligent engineering data can, among other things, be enriched with information about kinematic limits, mass points, and physical limits as well as information on ports and connections.

All component manufacturers who make their product data ready for Industry 4.0 and digital product transformation, and want to provide engineers with maximum comfort and functionality in product development, can distribute their digital 3D CAD engineering data as well as digital twins via the AutomationML download portal. In this way, manufacturers can better reach their customers while at the same time increase sales.

More information about the AutomationML 3D CAD download portal can be found here.

Would you like to learn more about the 3D CAD download portal AutomationML and how you can make your product data ready for Industry 4.0? Then stop by for a visit at the InspireAutomationCamp (25 - 27 Februar 2019 in Esslingen, Germany) or at the Industry Forum 2019 (20 & 21 March 2019 in Augsburg, Germany).

Further information at:

www.automationml.org

www.cadenas.de/en