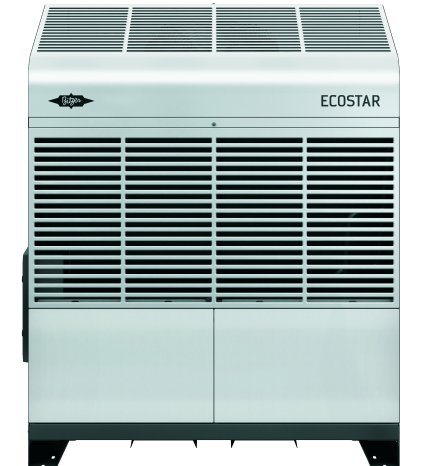

With the ECOSTAR LHV5E and LHV7E, BITZER has developed two air cooled and particularly energy efficient series of condensing units. The new ECOSTAR series clearly exceeds the specifications in the EU Ecodesign Directive thus offering users long-term planning security. From July 2018 the minimum efficiency performance standards (MEPS) requirements will become much more strict. This is why BITZER has taken early action to not just meet these strict efficiency criteria but even to exceed them.

Another advantage of the ECOSTAR condensing units is that their outstanding energy efficiency quickly pays for itself in the face of rising electricity prices. Low noise and reliable operation, ease of installation and use as well as their low maintenance are further distinguishing features of the LHV5E and LHV7E units.

An efficient solution for every application

With the new ECOSTAR LHV5E and LHV7E series, BITZER is also significantly enlarging its range of air cooled condensing units and now has the right solution in its range for every problem. Users can choose between three models of the LHV5E and from ten models of the larger LHV7E. Both series of condensing units have an improved mini-channel condenser, which means they need less refrigerant charge, while at the same time being more efficient than their predecessors.

The new ECOSTAR condensing units also have electronically commutated fans to save lots of electricity with the latest generation of active PFC monitoring. Users can smoothly adjust the speed and power of the fans and of the integrated ECOLINE VARISPEED compressor. In this way it is possible to operate with optimised energy requirements with a low number of switching cycles. The new condensing units also boast a reliably long useful life and low maintenance requirements. Devices can be quickly installed on-site thanks to the control electronics being factory-wired, making them immediately ready-to-operate. The ECOSTAR’s integrated controller automatically adjusts the compressor speed as well as the fans to match the actual cooling load, i.e. the ambient temperature, making the overall system especially efficient. Using the BITZER Electronics Service Tool (BEST) users can also adjust the characteristic curves for unusual applications via Bluetooth.

Flexible range of options

Depending on the choice of model, the condensing units are designed for use with the refrigerants R134a, R404A, R507A, R407A, R407C and R407F, so that BITZER can cover a wide range of applications. Additional refrigerants with a low global warming potential (GWP), for example R448A, R449A, R450A and R513A have already been programmed into the firmware so that they are available on request. With their robust and corrosion-resistant housing, the systems can be used outdoors, due to their compact size they can just as well be used in smaller equipment rooms. As the running noise is particularly low thanks to the integrated sound absorber and the noise-optimised airflow, the condensing units are suitable for use in locations sensitive to noise such as in a hotel courtyard. The integrated winter start feature allows the compressor to be started even at cold times of year when the ambient temperature falls below the saturated suction temperature.

Control made easy

Users can control and monitor the new ECOSTAR condensing units remotely via an Ethernet LAN connection or via the Internet and a Modbus RTU. In addition, BITZER has added a menu for the LHV5E and LHV7E to the latest version of its free BEST Software so that they can also be controlled like this. Using Bluetooth 4.0 the ECOSTAR unit can also be operated using the password protected controller from a distance of 30 m if in line of sight. Manual control and monitoring is also possible via the LCD display in the controller’s housing. With the help from a new function in the current firmware, up to four ECOSTAR condensing units can be connected via Modbus. They then form an ECOSTAR control network and, working ideally together, the temperature of a cold store can be controlled without their refrigerant circuits having to be connected.

Improved software means more protection

The ECOSTAR condensing units’ optimised software provides a number of improvements. Thanks to the updated emergency mode, the compressors and fans will continue to work at the same speed even if the sensors fail. If sensors only fail sporadically, e.g. due to a loose contact, then the emergency mode will automatically be deactivated. If the sensors work normally again, the unit will continue to work independently.

Also, frequency ranges can be skipped without the need for a BEST converter thanks to the improved avoidance of resonances. The update now enables the external access to be configured. An optional alarm signal can be set that sounds whenever the external enable is disabled.

In the new night mode, the firmware also limits the maximum speed of the compressor and the fans so that operating noise lies below 45 db(A) (-10 °C/32 °C/20 °C R134a). Declarations of conformity and supplementary performance datasheets corresponding to EU requirements are available on the BITZER web site for the ECOSTAR condensing units. These documents can also be generated using the BITZER Software.

Link to the BITZER Software:

https://www.bitzer.de/...

Link to the BEST Software:

https://www.bitzer.de/...

■

The BITZER Group is the world’s largest independent manufacturer of refrigeration compressors with sales companies and production sites for reciprocating, screw, and scroll compressors as well as heat exchangers and pressure vessels all over the globe. In 2015, 3,400 employees generated sales of €686 million.

Overview of images

Images may only be used for editorial purposes. This usage is free of charge if "Photo: BITZER" is given as the source and a complimentary copy is forwarded to us. Changes to the images – apart from cropping to the main motif – are not permitted.