Energy efficiency and the use of natural refrigerants are today among the key success factors for the economical operation of refrigeration systems in retail, food production and wholesale. Regulatory frameworks, such as the F‑Gas Regulation (EU 573/2024), which stipulates an accelerated phase‑down of fluorinated refrigerants by 2050, as well as tightened efficiency standards, are driving these developments. Investments made today must already meet the requirements of tomorrow.

Demand for future‑ready solutions for commercial refrigeration is rising rapidly. At EuroShop, BITZER demonstrates how this transformation can be successfully shaped. As a reliable partner for system manufacturers and operators, the company presents technologies and components for natural refrigerants such as CO₂ (R744) and shows how intelligent capacity control can significantly increase efficiency – particularly in part load operation – and reduce operating costs. Even small adjustments can deliver noticeable efficiency gains.

ECOLITE CO₂ condensing units: a simple and safe entry into CO₂ applications

At EuroShop, BITZER is presenting the first model of the new ECOLITE CO₂ family – the start of an upcoming series of condensing units specifically optimised for the natural refrigerant CO₂ (R744). These condensing units offer users in the commercial sector a future‑proof alternative to HFC refrigerants and enable an easy and reliable entry into CO₂ technology, which is increasingly establishing itself as the standard in commercial refrigeration. Whether it is for a kiosk, small convenience store or supermarket, the ECOLITE CO₂ condensing units can be used flexibly for low‑temperature and medium‑temperature applications in all climate zones. All components are perfectly matched to each other. The plug‑and‑play concept allows quick and effortless installation and commissioning, while the service‑friendly design facilitates maintenance work.

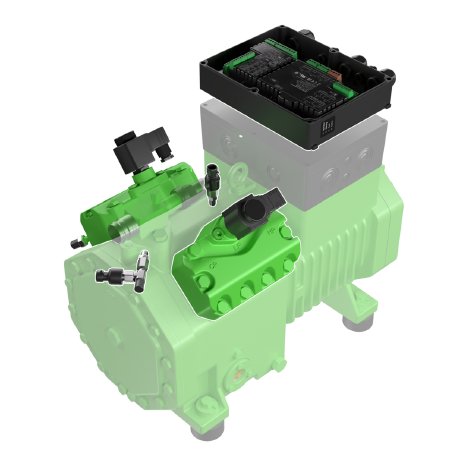

The heart of the condensing units is a specially developed two‑stage CO₂ reciprocating compressor from BITZER, equipped with the IQ MODULE CM‑RC‑02 and extension board. The IQ MODULE handles the functions of the condensing unit and automatically controls the high‑pressure control valve to ensure optimum high‑pressure levels. For even more efficient operation, especially at part load, the compressor is speed controlled via the integrated VARIPACK frequency inverter. The unit can also be ordered ex‑works with heat recovery – ideal for further optimising system efficiency and reducing operating costs.

The ECOLITE CO₂ model on display covers a cooling capacity of 25 kW* in medium‑temperature applications (MT) and 15 kW* in low‑temperature applications (LT) (*operating points: tamb = +32°C, t0 = –10°C (MT) at 60 Hz, t0 = –35°C (LT) at 70 Hz, Δt0h = 10 K, Δtcu = 1 K).

Advanced capacity control as a key to energy efficiency

High energy efficiency pays off twice for operators: it reduces energy consumption and therefore operating costs – and strengthens competitiveness at the same time. Precise temperature control is also crucial for the quality of sensitive food products. For this reason, efficiency across the entire life cycle should remain in focus.

BITZER offers a coordinated combination of compressors and technologies for capacity optimisation. At EuroShop, visitors can learn more about the mechanical capacity control VARISTEP, the external VARIPACK frequency inverter and the IQ MODULE CM‑RC‑02. These technologies are suitable for new systems as well as for modernising existing ones, are user‑friendly and easy to integrate.

The IQ MODULE CM‑RC‑02 is standard on ECOLINE reciprocating compressors from the C3 series onwards. Intelligent functions optimise installation, operation and maintenance. For example, the application limit protection uses the actual operating limits to the fullest and ensures safe operation. In addition, the IQ MODULE facilitates the implementation of advanced capacity control concepts that allow precise adaptation to actual cooling demand: the mechanical VARISTEP capacity control, for instance, can be connected via an extension board with minimal wiring effort and controlled directly via the module.

PERFORMANCE KITS for ECOLINE reciprocating compressors: easy retrofitting

After modifications in supermarkets, such as the installation of glass doors on refrigerated cabinets, adapted capacity control is often essential for high energy efficiency and reliable system availability. For this purpose, BITZER offers special retrofit solutions. With its PERFORMANCE KITS, the company presents simple ways to equip existing compressors with additional functions. The PERFORMANCE KITS are suitable for ECOLINE PRO reciprocating compressors for hydrocarbons (orders from 11 November 2024 onwards) and for the ECOLINE series for HFC/HFO refrigerants that were not supplied with the IQ MODULE CM‑RC‑02 ex‑works.

Retrofitting is quick and does not require major effort: with the ENERGY KIT, for example, the mechanical VARISTEP capacity control can be easily and safely retrofitted. The kit is mounted directly on the terminal box of the existing compressor, while the wiring is done at the module – without complex modifications in the control cabinet.

BITZER and Wurm: intelligent compressor technology meets smart system control

BITZER and the automation technology hardware and software specialist Wurm are exhibiting together this year with a shared stand at EuroShop. Under the motto ‘Technology that connects’, the two companies demonstrate in a shared area of the stand how their technologies interact, using a transcritical CO₂ system as an example.

The entire system is controlled by the overarching Wurm controller. This communicates via Modbus RTU directly with the IQ MODULE CM‑RC‑02, which is integrated into the terminal box of the ECOLINE four‑cylinder reciprocating compressor used. This ensures that operating data and warning messages feed directly into the central control strategy – for optimised system operation and high availability. Wurm has been part of the BITZER Group since 2019.

■

As an independent specialist for refrigeration, air conditioning and heat pump technology, BITZER is present all over the world: with products and services for refrigeration, air conditioning and process cooling as well as transport, BITZER ensures optimum temperature conditions for trade in goods, industry processes and indoor climate control – always striving for the highest possible energy efficiency and quality. BITZER is represented all over the world with 75 sites in 41 countries, including its sales companies and production facilities. Trade and service partners included, the BITZER network of manufacturing, development and sales extends to almost all countries in the world. In 2024, 4,500 employees generated a turnover of €1.12 billion; expenditure for research and development totalled €67 million.

www.bitzer.de

Overview of images

Images may only be used for editorial purposes. This usage is free of charge if ‘Photo: BITZER’ is provided as the source and a free copy of the publication is sent. Images may not be modified or altered, except to crop out the background surrounding the main subject.