Berthold offers measurement equipment and solutions for many demanding locations in the steel making process.

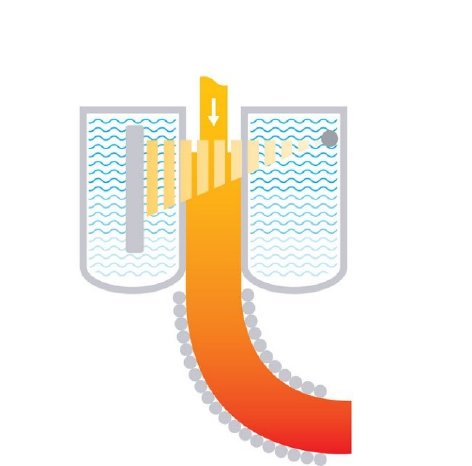

Level measurement in continuous casting molds

A precise and quick measurement of mold level lays the foundation for the production of high quality steel and the reliable prevention of steel overflows and breakouts. The Berthold mold level systems fulfill this role reliably and accurately. Several thousand strands throughout the world are equipped with Berthold systems.

Berthold Technologies provides measuring systems to solve this challenging measurement application. Depending on the requirements and measurement conditions, the optimum technology is selected.

Moisture measurement of coke and iron ore/concentrate in bunker, silo, or conveyor belts

The moisture content in the coke and the iron ore/concentrate being fed to a blast furnace is of great importance for thermal control of the blast furnace process. An online moisture measurement at the bunker provides real-time information on the moisture content before the material enters the blast furnace.

No matter what you want to measure, please visit us at the METEC Düsseldorf in hall 4 /G30 or just talk to us, we are happy to advise you or to learn more, visit our website:

https://www.berthold.com/...