The measuring system provides continuous and real-time information on the current water content or dry matter on a wide range of dairy products. The measurement can be applied directly in the main stream, therefore a bypass is not required. The materials used, which are FDA and EHEDG approved, allow easy cleaning and are resistant to high temperatures, acids and bases. Furthermore, performance is not affected by colour, viscosity, or inhomogeneity of the product.

Typical Applications:

- Butter

- Cream cheese

- Margarine

- Yogurt

- Curd

- Non-dairy plant-based alternatives

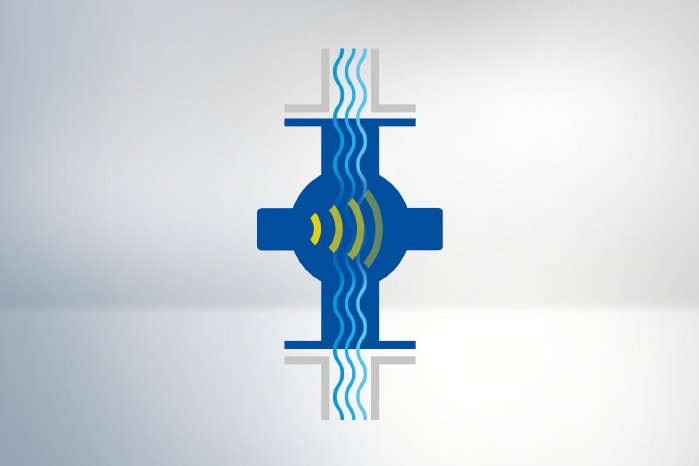

- Multi-frequency technology for dynamic plausibility control of the raw signal

- Representative microwave measurement captures the entire pipeline cross section

- Precise and reliable measurement < 0.2 wt.% (standard deviation)

- Online monitoring of the water or solids content during production

- CIP and SIP resistant materials

- Low-wear and maintenance-free

- Production optimisation

The measurement system generates microwaves that interact with the water molecules due to their high dielectric constant. This interaction causes an attenuation of the microwave energy, which can be detected as phase shift and attenuation. Since the phase shift and attenuation change are directly proportional to the water content in the product, the concentration or solids content in the medium can be determined with high accuracy. The superior multi-frequency technology from Berthold ensures very stable and reliable measurements, unaffected by interfering reflections or resonances from the measuring environment.

For further information please visit this link: www.berthold.com/dairy