The leg length in the most compact of the new angular gears is shorter than a matchstick. Ketterer offers seven sizes, featuring legs from 32 to 60 mm long. The angular gear meets many needs in installation, assembly and automation engineering. Further potential areas of application include shading and building engineering, as well as mechanical engineering.

In principle, the gear can be used for any deflection of a linear movement as well as being ideally suited to swivel motions. The applicable areas of deployment in plant construction or handling systems particularly include driving conveyor belts, adjusting the width of conveyor belts or swivel arms as well as adjusting positioning units and pallet systems. The Ket-Bee 200X is used in shading technology applications to adjust slats and other shading elements.

“The need for compact dimensions meant we had to use appropriate materials and prioritize the gear teeth quality. Accordingly, even the most compact model, with a leg length of 32 mm x 32 mm can guarantee maximum torque", explains CEO Odin Jäger.

The quality of the Ket-Bee 200X is reflected in its long service life and high power density. One reason for this is the use of top-quality materials. The angular gears comprise surface-hardened steel bevel gears and top-quality ball bearings for input and output drive. All of which makes them ideal to withstand the high stresses imposed by mechanical engineering. The precision-manufactured steel bevel gears have a radial clearance of just 3° ± 1°. This means the gear operates virtually noiselessly as well as being low-wear and maintenance-free. The gear ratio is 1 for all versions: 1, with torques and a power spectrum – depending on size – ranging from 0.1 to 10.0 Nm.

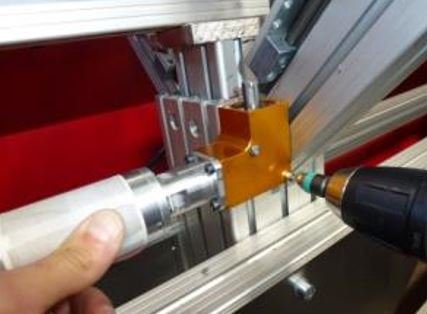

Another special feature Ketterer offers are the standardized interfaces. This means positive power transmission via feather key and a uniform hole pattern for mounting.