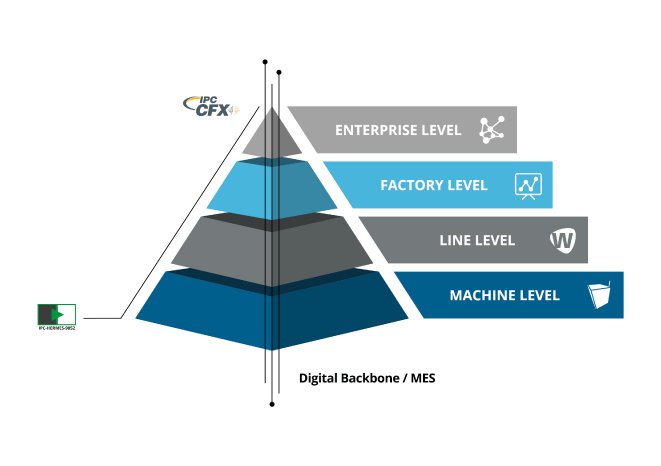

At its Booth 1436 in the Anaheim Convention Center, global player ASMPT will once again demonstrate that it covers almost the entire SMT production chain with its products and services and functions as a trendsetter for the industry. At this year’s IPC APEX EXPO, ASMPT will present its holistic hardware and software innovations for electronics manufacturers that range from the machine and line level to the factory and enterprise levels. Of particular importance will be the company’s Intelligent Factory concept with its holistic approach to integrative data analysis and usage that covers the entire factory and reaches across production locations. It optimizes processes, minimizes errors, improves material flows and deploys employees based on their qualifications in a highly effective manner – all while never losing sight of maximizing the return on investment.

Greater yields with existing production equipment

“Thanks to interfaces such as IPC-2591 CFX, you can now combine data from ASMPT machines and third-party systems and use it for in-depth analyses and improvements,” explains Mark Ogden, Marketing Manager Americas at ASMPT. “If you consistently implement the Intelligent Factory principle, you will quickly realize that you can get more out of your existing production equipment with this holistic, data-driven strategy: more productivity, more quality and greater yields. Interested visitors can find out from the experts at our booth what this looks like in practice.”

A complete production line

ASMPT will present a complete SMT production line at the IPC APEX EXPO 2024. It starts with a DEK TQ solder paste printer, whose output will be checked and automatically improved, if necessary, by a Process Lens SPI system. They will be followed by the highly flexible SIPLACE SX and the high-speed SIPLACE TX placement platforms. The machines will be complemented by a new, automated paste transfer system and equally new quick-change squeegees for solder paste printing, the high-precision TWIN pick-and-place head for the end-of-line placement of large, heavy components and special designs, as well as measuring devices for placement forces and electrical properties that can be easily added thanks to their standard feeder formats.

Software that adds real value

In the software area, ASMPT’s WORKS Software Suite plays an important role for all workflows on the SMT shop floor with applications such as WORKS Logistics for material flow optimization, WORKS Operations for effective personnel deployment across multiple lines, WORKS Monitoring for keeping track of important production parameters, and WORKS Optimization for quality optimization along the entire SMT line, which integrates SPI and AOI systems regardless of manufacturer. Other interesting components in ASMPT’s software portfolio include SMT Analytics for process analysis and optimization, Factory Equipment Center for production-wide asset and maintenance management, and the AI and NLP-based Virtual Assist, the personal assistant that engineers and technicians can access via their smartphones.

Visitors will also be able to learn about the training offerings of the ASMPT Academy as well as the modern MES from ASMPT’s software subsidiary Critical Manufacturing that was designed especially for the needs of the electronics manufacturing industry. “A visit to the ASMPT booth is always worthwhile,” says Ogden. “Here, visitors can experience live and in person how ASMPT hardware and software work together, how the Intelligent Factory combines standalone operations into an integrative whole, how SMT manufacturers can meet the ever-growing requirements of the global market, and how they can implement the Intelligent Factory step-by-step in their companies.”

The ASMPT SMT Solutions segment

The mission of the SMT Solutions segment within ASMPT is to implement and support the Intelligent Factory at electronics manufacturers worldwide.

ASMPT solutions support the networking, automation, and optimization of central workflows with hardware, software and services that enable electronics manufacturers to transition to the Intelligent Factory in stages and enjoy dramatic improvements in productivity, flexibility, and quality. With its integrated open automation concept, ASMPT opens the door for its customers to economically feasible automation, entirely in accordance with their individual requirements – modular, flexible, and vendor-independent.

The product range includes hardware and software such as SIPLACE placement solutions, DEK printing solutions, inspection and storage solutions, and the Software Suite WORKS. With WORKS, ASMPT offers electronics manufacturers high-quality software for planning, controlling, analyzing and optimizing all processes on the shop floor. Maintaining close relationships with customers and technology partners is a central component of ASMPT’s strategy.

For more information about ASMPT SMT Solutions, visit smt.asmpt.com.