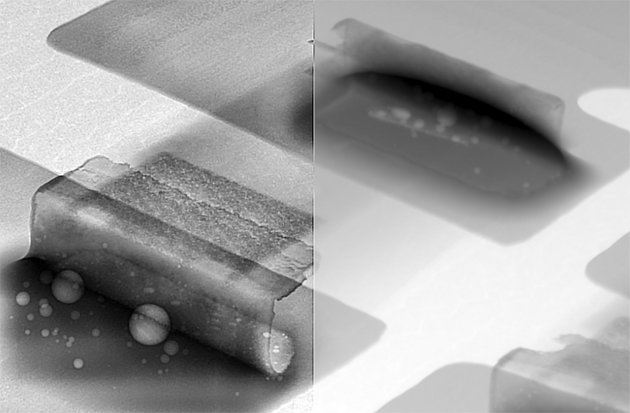

Although automatic defect recognition can be an integral part of production, human interpretation remains indispensable. To support fast image inspection, the YXLON software with the advanced HDX Imaging Engine provides an outstanding real-time image quality enhancement that, depending on part and application, automatically optimizes the image for the inspector with just a single click. Grey values are optimally adapted to the human eye. Four microfocus X-ray systems will be available for live demonstrations at the YXLON booth no. A2.133 in order to showcase this outstanding technology. As always, electronic parts which visitors bring with them for inspection are very welcome.

In addition, the product “SmartLoop”, which was introduced at the SMT exhibition in May, will also be available for demonstration. On one hand, the YXLON booth will be conveniently located near the Mirtec sales partner PB TEC Solutions, who will have the Mirtec inline 3D AOI system in their booth. This will enable the connection with a nearby YXLON microfocus X-ray system Y.Cheetah, providing a live presentation of “SmartLoop”. On the other hand, in hall A4-booth 506 NPL and SMART Group will showcase the daily special feature ‘Solder Paste & Solder Joint Automatic Inspection Experience’, where the Mirtec AOI system and the YXLON Cheetah microfocus X-ray system will be connected to a production line demonstrating their joint operation by using “SmartLoop”.

With “SmartLoop”, suspicious parts detected by the AOI system can be inspected in detail using X-ray, providing exact information on the flaw types. All information gathered enables precise analyses and the recognition of trends. This feedback is the basis for optimizing production processes and significant yield improvements.