As a rule, the race for the highest performance and the lowest system and lifecycle costs means that less and less attention be paid to designs. Since the constant evolution of new applications results in a multitude of servo drive trains with different characteristics, users are increasingly challenged to find the optimum product for their particular needs, making qualified technical advice vital.

TPK+ - double power

The new TPK+ right-angle gearhead from alpha getriebebau GmbH offers a double technology advantage for all applications with high reduction ratios (i=12 or more). It opens the door to far-reaching enhancements for numerous key applications in the machine building and automation industries.

Workpiece manipulators, rotary tables, tool changers and plates, swivel axes, the seventh axis of industrial robots, rack-and-pinion handling axes and XYZ-axes in production machines are just a few of the many potential uses.

TPK+ is a two-stage right-angle gearhead for servo applications featuring a robot flange according to ISO 9409 (without a pin). It is equipped on the output side with the alpha TP+ planetary gearhead introduced just last year. The focus of TPK+ is on power density, notably in the torque, the torsional stiffness and the torsional backlash.

This double technology advantage is the sum of the following components:

- An extremely precise, helical-toothed planetary gearhead stage is mounted at the TPK+ output. Optimised helical gearing not only assures the high power density, positioning accuracy and stiffness typical of planetary gearheads but also facilitates exceptionally smooth running.

- Thanks to the hypoid gearset at the input (up to i=10 in a single stage), there are now many applications in which a two-stage gearhead can take the place of a three-stage bevel-planetary gearhead. Once again, unprecedented smooth running is guaranteed by the innovative hypoid teeth. Added to this, TPK+ offers high continuous speeds and up to 200% more torque than bevel gearheads.

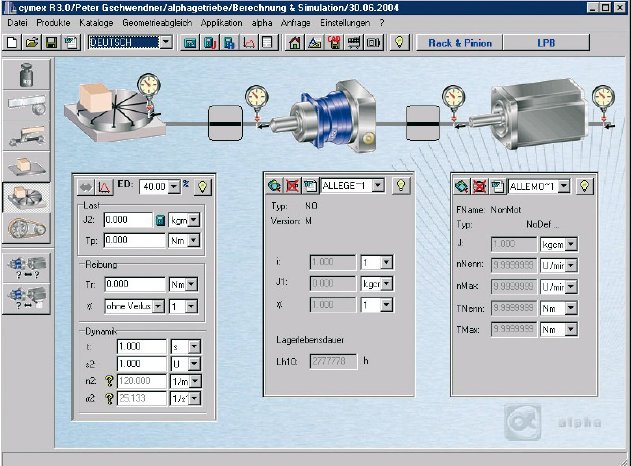

Like the other right-angle gearheads in the alpha family, TPK+ is integrated in cymex®, our unique sizing software application; cymex® allows an almost infinite number of drive solutions with different geometries, powers, moments of inertia, etc. to be identified with a few simple mouse clicks. In addition to the gearhead selection process, cymex® also optimises the other drive train components, including the motor and the machine elements at the gearhead output. The cymex® "motor library" currently contains more than 4,000 popular servo motor types. As a result, the task of the designer is much less time-consuming and more straightforward, and changes to the load data can be applied to the gearhead and motor in a matter of seconds.

- TPK+ is available in four sizes with acceleration torques up to 1600 Nm. Its reduction ratio spectrum extends from i=12 to i=100 (mathematically precise), always in two stages. It boasts a torsional backlash of up to 2 arcmin (fatigue-resisting) and runs at up to 6000 rpm. Thanks to the universal alpha motor mounting system, this right-angle gearhead is compatible with any servo motor. It has lifetime lubrication, can be installed in any position and is ideally suited to all servo applications. The standard delivery period for TPK+ is two weeks, but this time can optionally be cut to 48 hours with the alpha speedline service. TPK+ is part of a larger product family of right-angle gearheads, each with its individual technical focus yet at the same time compatible with all the others. alpha can thus manufacture the optimum right-angle gearhead for practically any application.

The benefits of TPK+ at a glance:

- Smaller sizes owing to the powerful planetary stage.

- Improved end product quality.

- Only a third of the weight of servo worm gearheads with similar torque.

- Design work is simplified, e.g. TPK+ can replace cam mechanisms or combinations of several gearhead stages/timing belts. The low torsional backlash of the integrated TP+ planetary stage plays a crucial role in making this possible.

- Better value for money (compared to bevel-planetary gearheads) with a wide range of reduction ratios because only two gearhead stages are needed instead of three.

- The superior torsional and tilting stiffness is reflected in the increased precision of dynamic processes and the resulting higher productivity.

- Smooth running means higher travel speeds free from irritating vibrations.

- As a full service supplier, alpha is excellently placed to identify new and better drive solutions: TPK+ can optionally be supplied with alpha's rack-and-pinion system.

- With its high torsional stiffness, rugged design and optional binary reduction ratios, TPK+ offers unrivalled advantages for "endless positioning" applications.