The key to the significantly increased strength at the tooth root lies in the production process: the use of a casehardening steel in conjunction with carburisation has a crucial impact on the rack's ability to withstand stress. Carburisation also facilitates a much higher linear force without altering the geometry. As a result, it is possible to downsize the rack to the next smaller module - or transmit higher forces with the same module - without compromising its performance values. The quantum leap achieved by WITTENSTEIN alpha in rack performance is the outcome of "evolution through interaction" - a strategy for intensive collaboration between designers, developers and process and material specialists. The tight integration of several core competencies within the WITTENSTEIN Group forms the backbone for this highend innovation that offers unbeatable value for money.

The details are embedded in the system

The carburised rack rounds off WITTENSTEIN alpha's new "Performance System", meeting customer demands for ever more compact solutions without any loss in quality or performance. WITTENSTEIN alpha delivers precisely this added value with its marketleading gearheads and optimally matched drive systems. As the developer and manufacturer of all system components, WITTENSTEIN alpha possesses all the required expertise in the areas of gearing, engineering, manufacturing and applications to cope with this challenge. We not only understand the synergies of component interaction: even more importantly, we know how to leverage them as efficiently as possible.

Our cymex® sizing software guarantees careful selection of the individual components needed for each application. Customers are assured the optimum possible combination of gearhead, pinion and rack for their particular motor. As a total system provider, WITTENSTEIN alpha warrants the functionality and performance characteristics of the designed solution. Together with the high quality standard of every single one of the proven components, this creates a real innovative lead for a comparatively small investment.

At a glance: the new Performance System

Based on the new rack, WITTENSTEIN alpha has broadened its already wide portfolio with the new Performance System:

- Performance System for maximum dynamics and feeding force when only limited space is available for installation

- Precision System for exacting dynamics and precision requirements in highend applications

- Smart System for mounting with more degrees of freedom in flexible applications

- Economy System for standard linear tasks

The new rackandpinion systems from WITTENSTEIN alpha define new benchmarks in terms of precision, dynamics and efficiency under even the most challenging conditions. They impress with their lighter weight, simple handling and transport, high dynamics, convincing energy efficiency and optimal controllability.

3 x 1 = one

Linear drive systems with gearhead, pinion and rack from a single supplier

The new rackandpinion systems impress with their high precision, dynamics and efficiency:

- High precision: Linear positioning accuracy of 30 µm even without a direct measuring system (Precision System)

- High dynamics: Acceleration up to 4 g and travel speeds of more than 300 m/min

- High efficiency: Enormous potential savings in terms of the total cost of ownership - as much as 20 euros per hour of operation for a mediumsized milling centre compared to a linear motor

Technical specifications

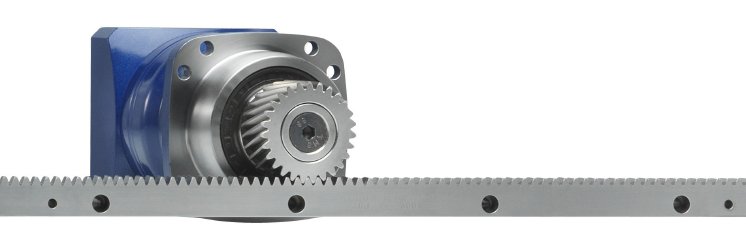

- Performance System: Performance Class rack (modules 2 to 6), compact PC+ pinion and lowbacklash planetary gearhead in the alpheno®, TP+ or TK+ series for feeding forces up to 76 kN.

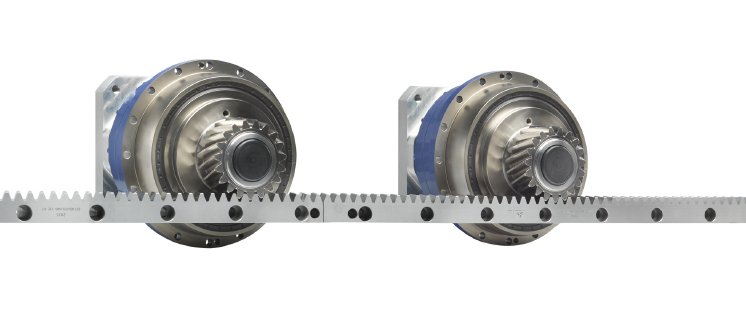

- Precision System: Premium Class rack (modules 2 to 6), highprecision Premium pinion with the lowbacklash SP+ und TP+ planetary gearheads, driven with high concentricity. Machine precision up to 5 µm can be achieved in a masterslave arrangement with TP+ gearheads.

- Smart System: Freely and flexibly mountable Smart Class rack (modules 2 to 4) as well as Premium or Standard pinion with freely selectable WITTENSTEIN alpha gearhead.

- Economy System: Value Class racks (modules 2 to 6) and Standard pinion for involute output shafts or shafts with a key.

Typical applications

- Grinding machines

- HSC portal milling machines

- Profile machining centres

- Turning machines

- Boring machines

- Laser machines

- Stamping presses

- Water jet cutters

- Machining centres for woodplastics compounds

- Plasma cutting machines

- Pipe bending machines

- Automation axes