For conducting the test, the substances in question are collected from the environment or can be generated by special aerosol generators.

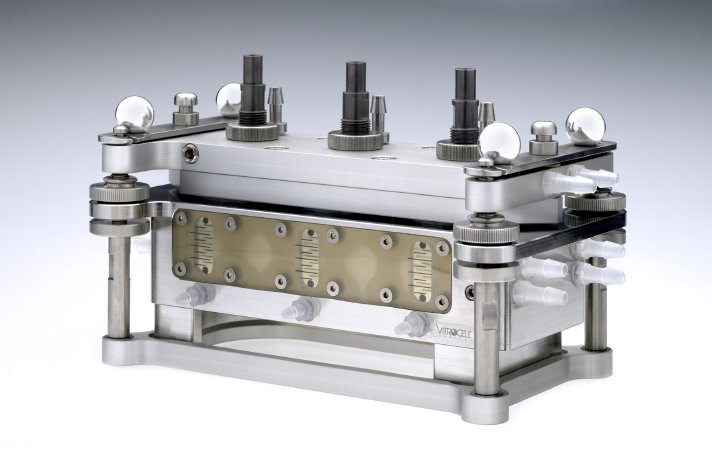

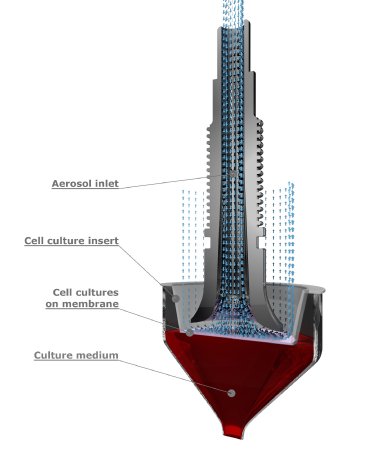

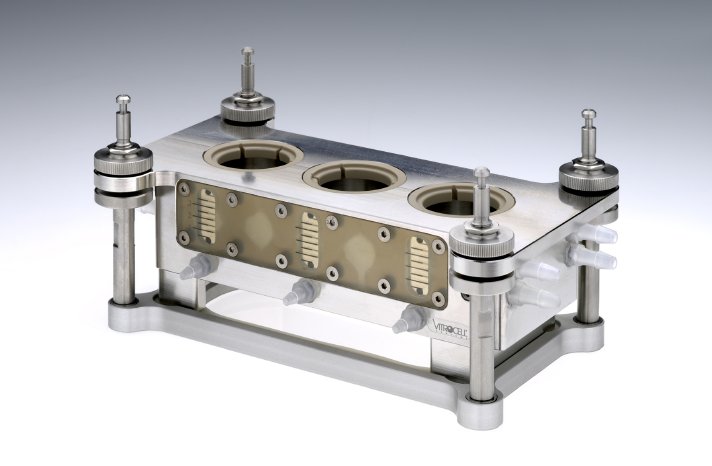

Then exposure takes place in the VITROCELL® cell cultivation and exposure module. For this purpose, the cells are first cultivated on membrane inserts (e. g. ThinCerts® from Greiner, Costar® from Corning or Falcon® from Becton Dickenson). The membrane inserts containing the cells are placed in the modules which are tempered at 37°C. The medium supply can be performed either static or by permanent exchange. The cells receive the cell culture medium from below through the membrane of the insert (cultivation at the air/liquid interface) in order to assure viability.

In direct exposure technology, the test atmosphere is delivered to the cells via specially surface treated stainless steel aerosol inlets at a low vacuum flow rate. As the cells are not covered with medium, they are exposed most efficiently at the air/liquid interface and can react therefore in an optimal manner. After exposure, the membrane inserts are taken out of the module and the cells are forwarded to standard routines for the analysis of a broad range of endpoints

VITROCELL® SYSTEMS offers a large product program of equipment for the in vitro analysis of airborne substances such as gases, nano particles and complex mixtures such as tobacco smoke. Either single equipment components or complete turn-key installations are delivered.

The VITROCELL® product range helps to reduce animal testing in the field of inhalation toxicology. VITROCELL® supplies leading companies in industry as well as leading research institutes.

More information: www.vitrocell.com