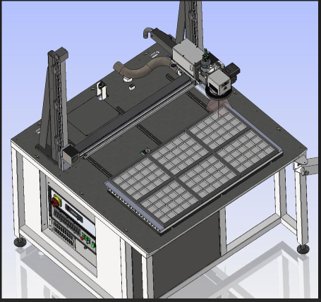

The SpeedMarker series from Trotec has been specially developed for industrial marking and engraving processes. Thanks to powerful fibre laser sources with up to 100 watts of power and a positioning and repeat accuracy of ±0.010 mm (when using TTL), even complex engravings can be realized with the highest precision - regardless of material or geometry.

Another advantage is their simple integration into existing production processes. The systems have a modular design, are compact, and do not require complex infrastructure. This reduces investment, set-up and training costs.

Application example:

A traditional Swiss watch manufacturer uses the SpeedMarker 1350 to mark unique codes on fully assembled watches shortly before delivery.

Thanks to the "autofocus camera," which automatically checks and adjusts the focus position (with a variation of up to 4 mm), and a camera solution (TTL: Through-the-Lens), which precisely detects the case contour (X-Y position) and features such as logos/drill holes (rotation), standard plastic pallets with foam inserts can be used. This eliminates unnecessary steps in the workflow by allowing the use of standard pallets for laser marking. Thanks to this exclusive TROTEC total solution, the average cycle time for laser marking has been reduced by ~40%. The proportion of watch cases with insufficient or heavy laser marking was reduced from 3% to 0.1%.

Precise control of laser parameters enables pin-sharp accuracy and consistent marking quality when marking finished watches made of materials such as stainless steel (316 L/904 L), titanium (grades 2+5), gold, and carbon, without the need for reworking.

“Our customers in the watch industry particularly appreciate the combination of precision, flexibility, and ease of use.” – Franz Eder, Manager of the Industrial Solutions Line, Trotec Laser

Further information on the SpeedMarker systems and their applications can be found at https://www.troteclaser.com/...