- The company connects machinery and digitalizes processes for other companies

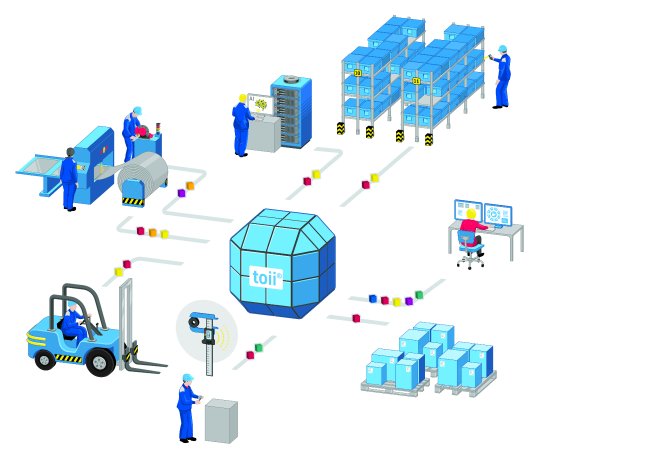

- The IIoT platform toii® optimizes, automates and visualizes data flows in production

- toii® enables machinery from a wide variety of generations and manufacturers to be equipped with self-learning systems and smart data functions

- Spin-off drives strategic "Materials as a Service" approach

Platform for digital transformation

One of the first core products is toii®. The IIoT platform developed in-house creates the conditions for machines of different makes and generations to communicate with each other around the world. The aim is to automate processes along the entire supply chain and make them more efficient.

"With toii® we have succeeded in bringing the digital transformation to the core area of our business: in the plant shops, machinery and warehouses," says Axel Berger, CEO of tkMIoT. "We now want to help other companies take this step too." Materials Services has successfully implemented toii® at more than 30 sites since 2017. One plant has increased its annual production by almost 10,000 tons while other locations have reduced downtimes by up to ten percent.

Digital transformation is essential

"The pace of innovation has picked up significantly in recent years and processes are becoming increasingly digitalized and connected," says Axel Berger. "In this environment it is becoming more and more important for companies to have competent partners they can rely on for innovative solutions to help secure competitive advantages and gain a foothold in Industry 4.0. We established tkMIoT to respond to this need." The step is also an important component in the further strategic development of Materials Services: With its "Materials as a Service" approach, the largest materials distributor & service provider in the western world is systematically expanding its service portfolio.

Start-up meets tradition

tkMIoT supports its customers throughout the transition to Industry 4.0: From advice on implementing IIoT technologies to support during the entire lifecycle of solutions and operation of the underlying platform. The company has an experienced team with extensive experience in industrial projects and combines a start-up culture with the traditions of a global group with more than 200 years of industrial experience.