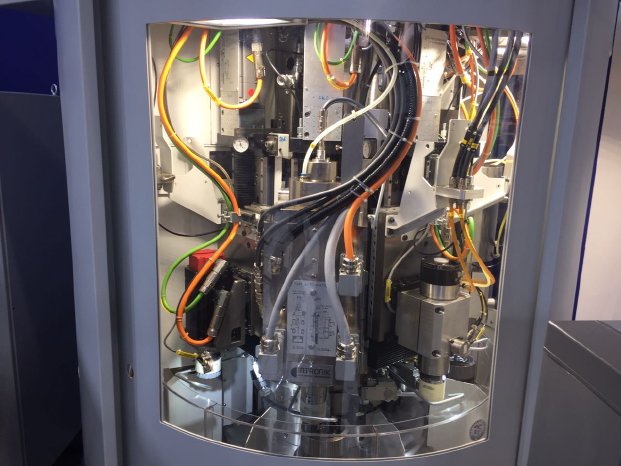

The 8 station machine for the combination processing doesn’t just ensure 100% compliance of all drawing dimensions for highly precise workpieces, but also the consolidation of the process stream. It generates significant cost savings. Oscillation sensors control the sensors and also the quality of the processes. In the area of active magnetic spindle technology, the magnetic fields of the bearings retain the spindle both radially and axially, and perform the feed motions.

The MicroStar iQ is equipped with a synchronous spindle, which is capable of varying and/or oscillating highly dynamic speeds during the process. Due to the speed variation the tool can always be kept in an easy-cutting range. HyperFinish processing is also possible with this system by overlapping the main oscillation with an additional high frequency oscillation.

A new HyperBrushing process that was developed especially for this machine ensures equal or even better results than those achievable by a high pressure deburring unit, which can thus be omitted from the whole process to save costs. This deburring technology with the special kinematics of the brushes improves the symmetrical rounding ratio of the flat surface to the casing and ensures more constant deburring results. That is particularly important in the case of holes in components used for injection technology, which may be subjected to pressures of more than 2,000 bar. Before the workpieces leave the machine, they are cleaned in a cleaning station with dry ice and an extraction system and then finally, their flatness is measured.

Based on the measured results, in the event of deviations from the drawing specifications, the program can make immediate readjustments in conjunction with PowerTilt in a closed control loop. PowerTilt automatically adjusts the flatness and the cross cut of finish stations. With EasyTilt calculation software is also available for highly precise adjustment of finishing units of the workpiece drawing.

Due to “gauging inside” with feedback of the results to the finishing units and monitoring the oscillations, measuring room capacity is also saved and the operator is significantly unburdened as s/he no longer needs to make quality-related adjustments.

In the case of frequently changing workpiece versions, the extremely shortened set-up times also have an incremental affect on output.

More information can be found at: Thielenhaus Technologies GmbH, PO Box 201855, 42218 Wuppertal/Germany, Tel. +49 (0) 202 481-0, Fax +49 (0) 202 45 04 45, or on the Internet at www.thielenhaus.com