We have sophisticated various types of elemental technologies nurtured by us to improve the

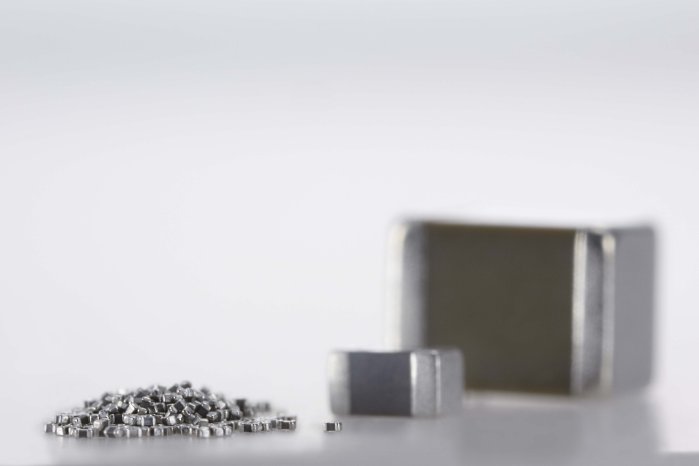

temperature characteristics of X7R (operating temperature range: -55 to 125°C) in our onventional products to X8L (-55 to 150°C). These products are available in a wide assortment of dimensions, from the 1005 size (1.0 × 0.5 mm) to the 3225 size (3.2 × 2.5 mm).

The products will be used for decoupling or anti-noise parts in automotive power trains such as

engines and transmissions. Production of the multilayer ceramic capacitors commenced at the company's Tamamura Plant (Tamamura-machi, Sawa-gun, Gunma Prefecture, Japan), KOREA KYONG NAM TAIYO YUDEN CO., LTD. (Sacheon-si, Gyeongsangnam-do, Korea) starting from May 2020.

Technology Background

In recent years, electrification and electronification of automobiles have increasingly progressed in step with the proliferation of electric and hybrid vehicles. Under this situation, demands for higher reliability have also risen for multilayer ceramic capacitors that are used in such automotive electronic parts. EMC measures are required for such devices to remove external and internally generated noise to prevent malfunction. In addition, as devices increase in functionality and use higher-density packaging, the interior temperature also increases, requiring multilayer ceramic capacitors to withstand such harsh conditions. In response this situation, TAIYO YUDEN sophisticated its elemental technologies to add automotive multilayer ceramic capacitors with an increased maximum temperature range of 150°C to its lineup. TAIYO YUDEN will continue to further expand its product lineup to respond to market needs requiring high reliability.

Application

Decoupling or anti-noise parts that can be used in automotive power trains such as engines and transmissions