Gentle transfer of treads

The Intralox DARB conveyor system provides gentle and precise 90-degree transfers of treads coming from the customer’s conveyor system and ensures proper handling and support of the tread without distortion or stretching, without the need to stop the conveyor for tread transfer.

90-degree transfers without stopping

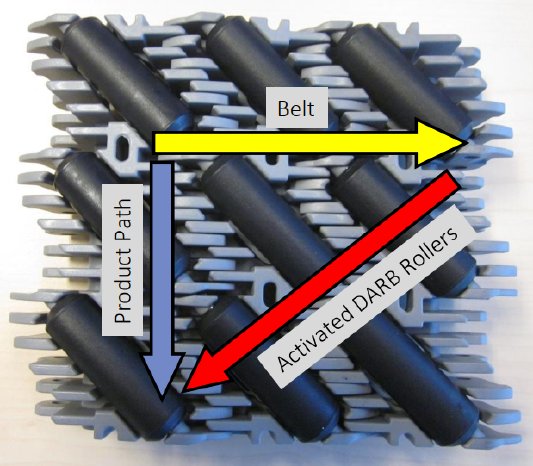

The system features two belt rollers on top of each other.

They drive one another when activated and rotate in opposite directions. Rollers are placed at less than 45 degrees to the belt travel direction while the product travels backward and sideways in relation to the belt, resulting in a true 90-degree product transfer.

Optimal support for strips

The belt rollers are activated X times or X pulses after the tread’s trailing or leading edge is detected.

The time or number of pulses is a constant and is set so that the belt rollers are activated when the longest tread is completely on the activation zone. Thus, the trailing edge is always at the beginning of the activation zone - or the leading edge is always at the end of the activation zone.

Automatic tread booking systems

Faster extrusion speeds and requirements for higher accuracy encouraged the tire manufacturer to replace the manual loading by automatic tread booking systems. More and more booker loading systems have been installed to get a grip on the problems associated with manual loading.

Avoiding manual handling

Tread deformation is a good example. Improper handling can cause transversal and longitudinal deformations.

Especially dimensions and weight of truck treads make it hard for operators to handle the treads in a proper and appropriate manner.

Automatic tread booking avoids the disadvantages associated with the manual tread handling.

Continuous Development

Automatic booker loading devices made by SYSTRAPLAN are well-known and used in the tyre industry for quality assurance of treads and tyres as well as for rationalisation.

SYSTRAPLAN, specialist for material handling equipment when it comes to flat materials, started producing auto booking and handling systems for the tyre industry in 1977.

This machine type has been continuously developed based on a large number of machines built and vast experience gained in more than 40 years.