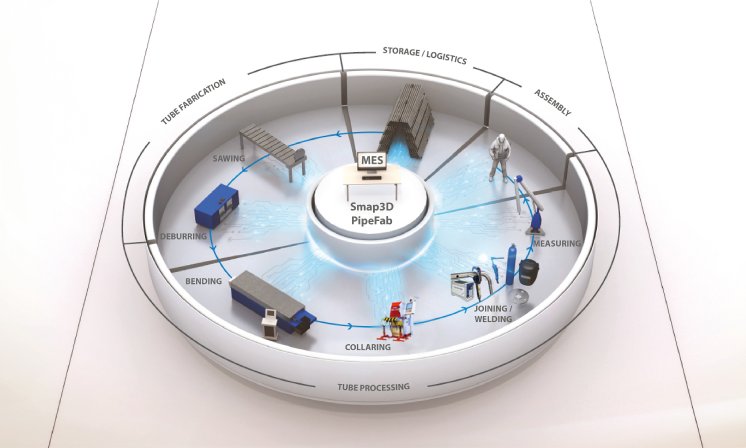

The Manufacturing Execution System connects pipe construction and fabrication by linking relevant design data with ERP data (e.g. master data) and technology data (e.g. welding gap) and storing the digital manufacturing process in a database. Machines that are connected via so-called "pilots" thus receive all the information required for flawless execution from the very first pipe. The data can then be fed back to other systems such as ERP or PDM/PLM for documentation. In addition, assembly processes and logistics (e.g. pallet tracking) can be mapped. Optionally, Smap3D PipeFab can be extended by additional functions such as batch tracking, warehouse management, welding documentation management and controlling.

Dynamic production planning

The solution can be directly integrated with the plant engineering software Smap3D Plant Design and thus also with the CAD systems Solid Edge, SolidWorks and Inventor. Alternatively, design data can be imported from other CAD systems via the STEP, IGES or PCF interfaces. Smap3D PipeFab enables dynamic production planning of a large number of individual orders, taking processes, machines and materials into account. The orders are broken down into lot size-optimized production units and then optimized for each process according to, among other things, set-up time, waste, utilization or material flow. This allows prefabrication of the pipes to be decoupled from the fabrication order. Maxim Lich, Managing Director of the software development house and solution provider Smap3D Plant Design, makes the advantages of the planning and control tool clear: "With Smap3D PipeFab, material and personnel can be planned efficiently. Dynamic production planning enables shorter throughput times to be achieved and setup times to be optimized."

Complete documentation and traceability

In addition, the MES solution combines functions for transferring and preparing product data for fabrication and functions for managing and documenting fabrication data and manufacturing sites. This ensures seamless documentation and traceability, paving the way towards paperless production and facilitating the creation of a knowledge database on the shop floor.

Flexible machine connection

Smap3D PipeFab fits seamlessly into the existing Smap3D Plant Design product range and thus represents an enrichment for the overall process of pipeline fabrication, explains Maxim Lich: "With this integrated MES solution, we have expanded our software portfolio in such a way that all processes from pipe design to production planning to the control of machines can now be implemented. This makes our plant engineering solution even more unique on the market." The direct integration of cutting, bending, collaring and welding machines from various manufacturers is the central building block of Smap3D PipeFab. Standardized interfaces already exist for the systems of the suppliers Pipe Bending Systems (PBS), T-Drill or Polysoude.

More information about the MES can be found at www.pipefab-mes.com/en/.