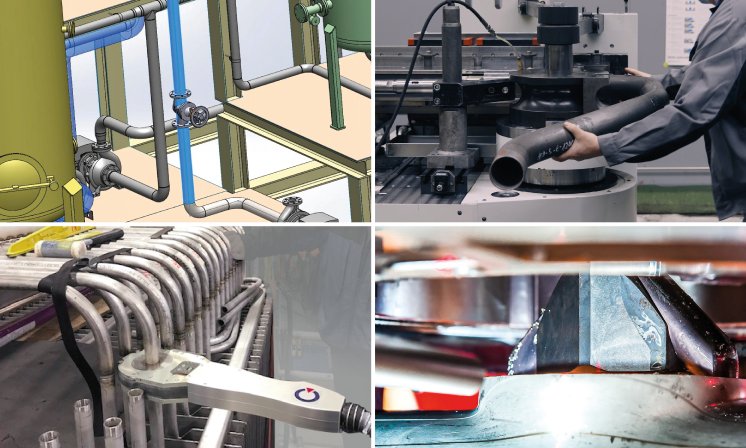

Already in 2021, the four companies presented their professional expertise in pipe construction, simulation, bending, orbital TIG welding and collaring of pipes to invited customers at the Plant Design and Piping Production World 2021. “Due to the positive response we have decided to further deepen and strengthen our partnership and integrate our acknowledged industrial solutions even more closely,“ said Maxim Lich, managing director of Smap3D Plant Design. Based on industry 4.0, this solution will interlink the construction, manufacturing execution control and processing of pipelines and will optimize communication and the exchange of data between the individual areas. This will save time and costs and will greatly increase the quality of the entire process.

At this year’s ACHEMA, the leading international trade fair of the process industry which takes place from 22nd to 26th August 2022 in Frankfurt am Main, Germany, the four business partners will present all aspects of this solution live at booth E115 in the so-called Digital Hub in hall 12.1. With the proven Smap3D Plant Design software packages, 2D flow diagrams (P&ID), 3D piping as well as isometric drawings for pipe manufacturing can be implemented. In addition, integrated simulation solutions can create the early assurance whether a planned pipe can be manufactured and processed. The seamless integration in the CAD systems Solid Edge, SolidWorks and Inventor will also be presented at the trade fair booth by the Smap3D partners Solid System Team, SolidPro and Mensch und Maschine.

The link between pipe construction and pipe processing/manufacturing is Smap3D PipeFab, a MES (Manufacturing Execution System) for process planning and control, that connects the relevant construction data to ERP data (e.g. master data) and technology data (e.g. welding gaps) and stores the digital manufacturing process in a database. The bending machines from Pipe Bending Systems, the orbital TIG welding products from Polysoude as well as the collaring, flanging and pipe cutting machines from T-Drill thus all receive the necessary information for the implementation and can subsequently send data for documentation purposes to other systems, for example ERP or PDM/PLM. Hence the bidirectional transfer of relevant data between Smap3D PipeFab and machines ensures efficient work processes in plant construction.

The positive effect of the partnership can also be seen in the pipe processing and manufacturing process: Pipe Bending Systems offers efficient pipe bending machines and precise pipe measuring systems. If plant construction companies combine these technologies with the T-Drill collaring, flanging and pipe cutting machines and with the welding systems from Polysoude, they will be equipped for any eventuality.

More information about the companies can be found under the following links:

Smap3D Plant Design: www.smap3d.com/en

Pipe Bending Systems: www.pipe-bending-systems.de/en

Polysoude: www.polysoude.com

T-Drill: www.t-drill.com