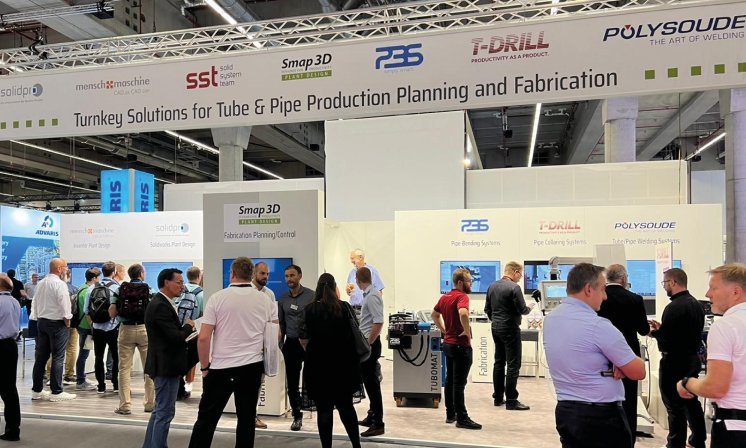

Companies from the process industry (e.g. chemical, beverage, food, pharmaceutical, hydrogen) or environment and water technology are faced with the task of increasing productivity and quality in the planning and fabrication of machines and plants including integrated piping, as well as reducing time and manufacturing costs. The turnkey solution from Smap3D Plant Design and its partners Mensch und Maschine, Solidpro, Solid System Team, Pipe Bending Systems, T-Drill and Polysoude precisely addresses these challenges. The approach found great interest among the international ACHEMA audience, which visited the joint booth in the Digital Hub in Hall 11. "The presentation of our complete solution attracted the ACHEMA visitors. In the discussions at the trade fair, it became very clear that companies in plant engineering are not looking for individual products, but rather a complete solution to face their challenges," says Maxim Lich, Managing Director of Smap3D Plant Design GmbH. "This is exactly what we were able to fulfill: a well thought-out turnkey solution, consisting of several coordinated products, at a single booth."

The partners' summary was also very positive. They welcomed being part of the continuous overall process from pipeline planning to fabrication. In the area of design, Smap3D Plant Design presented its software, which can be used to realize 2D flow diagrams (P&ID), 3D piping design and isometric drawings for pipeline fabrication, and to perform simulations. The seamless integration of the software package into common CAD systems was demonstrated by the renowned system houses Solidpro for Solidworks, Mensch und Maschine for Inventor and the Solid System Team for Solid Edge by means of the add-on Modular Plant Design. Smap3D PipeFab, a Manufacturing Execution System (MES) optimized for the planning and control of pipe fabrication, was also well received by visitors. In addition, Pipe Bending Systems' bending machines, Polysoude's welding guns and technologies, and T-Drill's collaring, flanging and pipe cutting machines were presented at the booth and even demonstrated in live operation. Smap3D Plant Design has maintained a deep partnership with the machine manufacturers for years.

"The trade fair appearance at ACHEMA has once again confirmed to us that partnerships are enormously important and promising, especially in the industrial environment," says Maxim Lich. "Pooling the know-how of individual plant engineering experts holds great potential. That's why we're looking forward to the exciting joint projects that emerged at the trade fair."