Hall 1 /Booth 1GA47

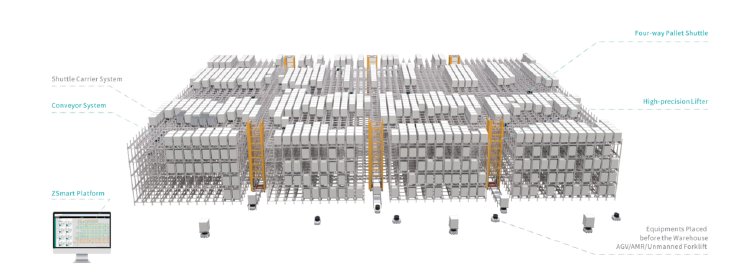

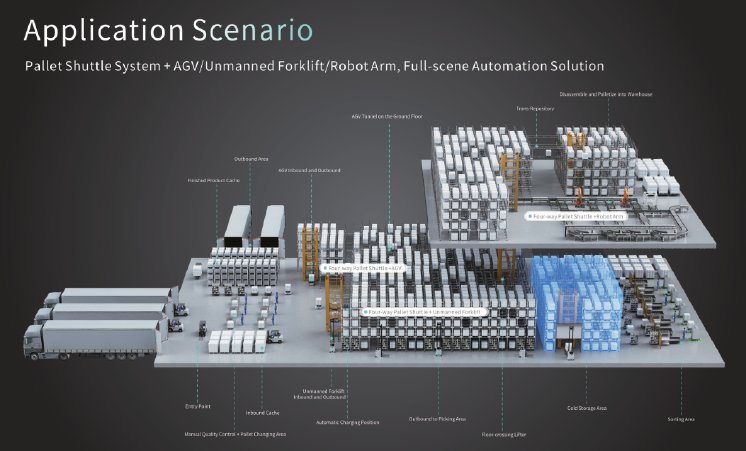

At LogiMAT 2026, ZS Robotics (Booth B16106) will present its latest pallet automation solutions, including the H150 four-way shuttle and the ZSmart intelligent warehouse system, demonstrating a new generation of pallet AS/RS engineered for 0 project failures, long-term operational safety, and exceptional ease of deployment and use.

ZS Robotics is dedicated to building the world’s safest and easiest pallet AS/RS. With a clear focus on four-way shuttle technology and intelligent robot management systems, the company delivers high-performance warehouse automation solutions designed for real industrial conditions—where being safe and easy to operate is more important than complexity.

Safe by Design

At ZS Robotics, safety is not treated as an add-on, but as a system-level principle.

From mechanical structure and motion control to traffic management and software logic, every layer of the system is engineered to minimize operational risk and ensure stable, repeatable performance in high-density pallet storage environments.

The H150 four-way shuttle is engineered for precise positioning, controlled direction changes, and reliable operation across a wide temperature range. Its design emphasizes load stability, accurate motion, and predictable behavior—key requirements for large-scale pallet handling in demanding industries such as retail distribution, cold chain logistics, pharmaceuticals, energy, chemicals, and industrial manufacturing.

Easy by Design

Ease of use at ZS Robotics does not mean reduced capability—it means clarity and operational simplicity.

The ZSmart intelligent warehouse system, composed of modular WMS, WCS, and RCS software, provides a unified and intuitive interface for warehouse operations and automation control. Real-time 2D and 3D visualizations allow operators to see and understand system status instantly, while standardized interfaces enable fast integration with upstream enterprise systems.

System configuration, shuttle deployment, and task adjustment are designed to be straightforward and efficient, reducing commissioning time and lowering operational complexity for both integrators and global customers.

Proven Worldwide

ZS Robotics solutions have been deployed across 200+ medium and large-scale enterprises worldwide, supporting a wide range of storage and throughput requirements. The systems have been validated in diverse commercial and industrial environments where stability, scalability, and operational transparency are essential.

Working with experienced system integrators, ZS Robotics delivers globally adapted warehouse automation solutions, combining engineering rigor with practical deployment experience.

LogiMAT 2026 Highlights

H150 Standard Four-Way Shuttle for pallet storage and handling

ZSmart Intelligent Warehouse System for warehouse and robot orchestration

ZS Robotics - Safety first. Easy always.