Monitoring of reactant and product quality

Precise monitoring of the starting materials already shows its advantages during the preparation of the brine. With LiquiSonic®, the concentration of the sodium chloride solution can be precisely adjusted down to 0.1 m%. Maximum saturation prolongs the life of the membranes during electrolysis and saves energy during subsequent concentration of the sodium hydroxide solution.

After electrolysis, the caustic soda solution (NaOH) still has to be freed from unwanted NaCl residues and then concentrated to the usual purity. With LiquiSonic®, this process can also be monitored and controlled in real time. High plant efficiency and unbeatable product quality are the result.

Application in the drying of chlorine gas

After the chlorine gas has been produced, the challenge is to reduce its process-related water content. For this purpose, hygroscopic sulfuric acid is used as a drying agent. The smallest deviations in acid concentration cause poor drying results and high costs or long-term plant damage, e.g., due to rust. LiquiSonic® allows checking the sulfuric acid concentration with an unbeatable accuracy of up to 0.03 m%. Poor chlorine drying results are thus a thing of the past.

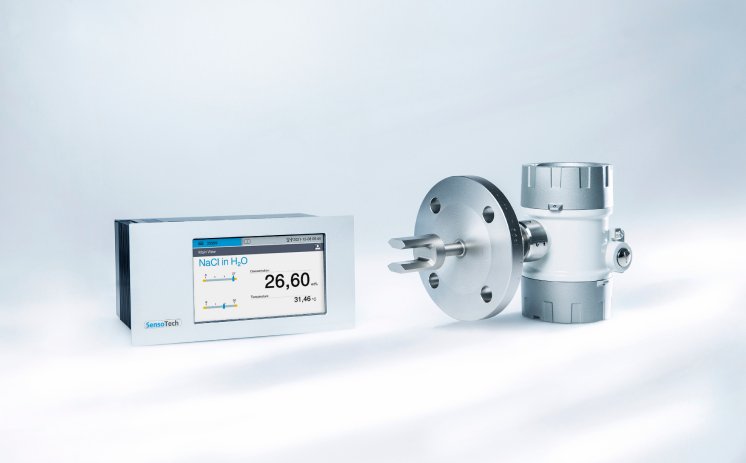

LiquiSonic®: The solution for inline process monitoring in real time

Many processes require fast reactions to changes or errors. LiquiSonic® reliably detects these deviations within seconds. Warnings can be issued via a variety of data interfaces - even by e-mail. Thus, users are always informed about the status of their process.