The XL SCAN solution can improve accuracy, feature resolution and throughput of micromachining of larger sized parts by synchronously controlling a 2D scan head and 2-axis XY stage motion. The scan solution incorporates the expert know-how from market leading scan systems with the long-standing experience of controlling mechanical axes. It provides highest precision within a virtually limitless working area, which is a key feature for various applications in electronics manufacturing.

Global technical support for XL SCAN

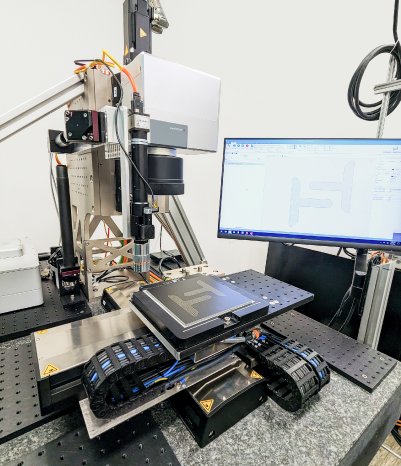

Laser machine builders design and setup complete systems precisely in line with the respective process requirements. But integrating very specific components, like an advanced micromachining scan system, is usually not their main focus. Recognizing this, SCANLAB collaborates with selected partners who bring a profound understanding of lasers, precision motion, optics and their applications in micromachining. These partners possess an intimate knowledge of the XL SCAN and offer solutions with this advanced technology, making it effortless to incorporate in manufacturing.

In Europe Busch Microsystems offers a full-integration service. For XL SCAN users in South Korea, a technical support center has been established in partnership with PRESTO SOLUTION. The services offered here range from pre-sales consulting, feature demos and individual testing sessions in an own laser application lab to commissioning and on-site support at customers’ facilities. Now the US-based Turner Laser Systems completes the global support offer with turnkey solutions and process development services in their laser laboratory.

All partners base their service offer on the proven technology partnership with ACS Motion Control and the software provider Direct Machining Control (DMC).