A gradual introduction of PFAS bans, staggered by product group and with corresponding transition periods, is currently considered certain. And even though there are currently indications that the bans are not expected to come into force before 2027, ROWA Masterbatch is already working intensively and successfully on the development and testing of alternatives.

Polytetrafluoroethylene (PTFE) is one of the high-performance plastics within the PFAS group of substances. Due to its non-polar structure, the semi-crystalline fluoropolymer has exceptional physical and chemical properties that enable a wide range of industrial applications. PTFE is used in industrial applications such as seals and coatings, in medical implants and prostheses, and as non-stick coatings in cookware.

PTFE is used as a versatile additive in thermoplastics. Among other things, it serves as a flame retardant to increase flame resistance and reduce dripping in the event of a fire, as a solid lubricant to minimize friction and abrasion, and as a polymer process aid (PPA) to improve processing properties – for example, as a lubricant and release agent in the injection molding of polyamides or the film extrusion of polyolefins.

Given the wide range of applications for PTFE, there is currently no universally applicable alternative as an additive. The selection of suit able substitutes depends heavily on the specific application and the specific requirements of the end product. ROWA Masterbatch works with customers to develop application-specific solutions for PFAS free products. The following is a selection of PTFE alternatives:

Lubricants are effective both during processing and in the end application: they facilitate demolding by reducing adhesion between the melt and the mold surface and later contribute to reducing friction and noise. Since classic lubricants are usually migrating substances, their effect is limited in time. PFAS-containing lubricants and PPAs can be replaced by suitable alternatives. ROWA Masterbatch has extensive expertise in the development of PFAS-free solutions for a wide range of applications and polymer types, including PET, TPU, TPE, PA, PC, styrene copolymers, polyolefins, and other engineering plastics.

Unlike classic lubricants such as stearates, waxes, or amides, solid lubricants – such as metal sulfides or graphite – are permanently bound into the polymer matrix and thus have a long-lasting effect. These “lubricants” improve the tribological properties and thus increase the service life of moving plastic components. Like PTFE, they reduce the coefficient of friction and abrasion loss.

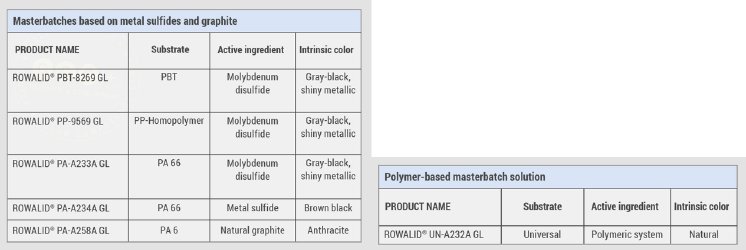

The portfolio of products developed to date using metal sulfides and graphite includes are those in the left table (s. picture).

ROWA Masterbatch also offers a PFAS-free, polymer-based masterbatch with permanent effect to improve the sliding properties and abrasion resistance of engineering plastics and rubbers. Unlike the products listed in the left table, this product can be individually colored (see table on the right).

As an expert in customer-specific and polymer-specific masterbatches, ROWA Masterbatch develops a suitable solution for every application.