Polyphenylene sulfide (PPS) is a high performance thermoplastic characterized by a combination of properties ranging from high temperature resistance to dimensional stability and excellent electrical insulation properties. Different standard ROMITRON® PPS compounds were recently offered by ROMIRA with a variety of characteristics such as high flow, elastomer-improved, low warpage, low mold flash, etc. This allows meeting a wide range of the customer requirements in different sectors from automotive to electronics and home appliance.

PPS reinforced with 40 % glass fiber (PPS GF40) is the main grade in the market that is widely used as it offers an excellent combination of strength, heat and chemical resistance. In particular, it is well suited for applications where long-term heat resistance is required (up to 210 °C continuously).

Although the standard grade PPS GF40 has very high continuous service temperature, like any other polymer, decrease in strength and rigidity occurs at elevated temperatures. The change in properties commence at temperatures higher than glass transition temperature (Tg) of PPS. This can limit the use of PPS GF40 compounds for the applications that high thermal stability is required. Other high performance polymers with higher Tg might be considered to be used, however, they are costly and special processing condition or tools need to be utilized.

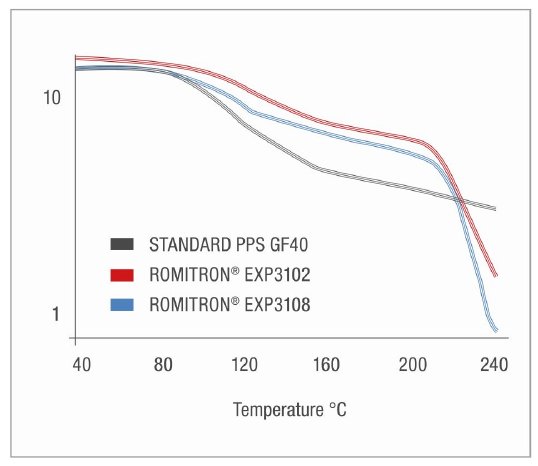

To fill the above mentioned performance gap, new ROMITRON® EXP3102 and EXP3108 grades have been developed with improved thermal stability. These grades are PPS GF40 blends, exhibiting higher storage modulus than standard PPS GF40 at temperatures above 100 °C (Please see test results in the diagram). The higher storage modulus proves the ability of these grades to retain properties at high temperatures.

Exemplary application can be high heat lighting systems/components where high stiffness and dimensional stability at a range of temperatures is mandatory.