Metal sheathed cables require high precision technology for the production process. Manufacturers need to be flexible in their production process. Efficient, flexible, with the corresponding performance.

Efficient process

Metal tape forming, welding and the subsequent jacketing process can be done inline in a tandem process. At the same time, the production speed as well as the product’s quality are maintained at a constantly high level. High productivity is especially provided by the continuous welding solution, which supports long product lengths and smooth production.

Flexible production

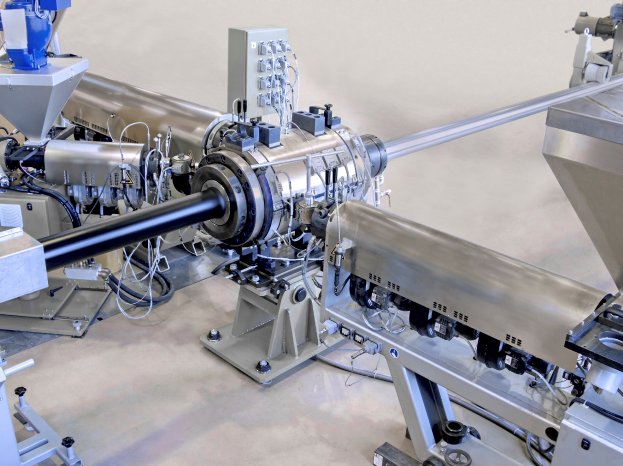

The Rosendahl RH-W metal tape forming and welding line is designed to process aluminum, copper and stainless steel on the very same line. The line is a state-of-the-art concept which is successfully applied at known references worldwide. It is flexible in processing different metals as well as in its entire production process. This is due to the fact that each of the production steps can be adjusted to a manufacturer’s needs, e.g. either inline or offline, smooth or corrugated. The options are manifold.

High performance

Depending on the product diameter, ranging from 40 mm to max. 200 mm, the line runs at speeds of up to 15 m/min. The tools are easy to change and the line’s performance can be tracked by the RIO line control system. This system reports and analyzes the process and output.

It is an all-in-one solution with many benefits for the final product.