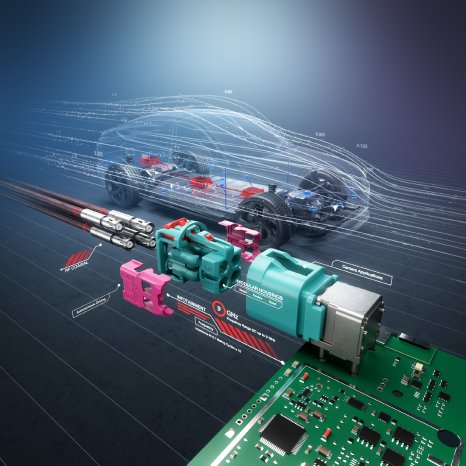

The compact coaxial connector system supports data transmission in the frequency range from DC up to 9 GHz and is currently already utilized by leading automotive manufacturers. It is ideally suited for applications requiring high data rates in tight installation spaces.

Thanks to its modular design, the system offers a wide range of configuration options. Straight and rightangled cable and PCB connectors are available, as well as single, double, and quad housing modules — including waterproof variants. Its robust, USCAR-compliant design with 50-Ω impedance ensures longlasting reliability, even under demanding environmental conditions.

RMC® is suitable for a wide variety of automotive applications, including infotainment systems, advanced driver-assistance systems (ADAS), camera systems, autonomous driving, car-to-X communication, and internet connectivity. It supports all common high-speed protocols, including APIX® , FPD-Link, GMSL™, MIPI A-PHYSM, PCIe® , USB, GVIF, HDBaseT™, and ASA Motion Link.

Advanced technical features for automotive applications

The RMC® series meets all established automotive standards and is USCAR-specified. Its reduced dimensions and modular architecture offer up to 80% space savings compared to conventional FAKRA connectors, making the RMC® series a cost-efficient solution for modern automotive electronics. The optional CPA (Connector Position Assurance) feature prevents unintentional disconnection. CPA can only engage when the connector is fully mated and correctly aligned, ensuring maximum connection reliability, even under harsh conditions.

The compact system design reduces installation space and overall vehicle weight while optimizing material costs. Rosenberger offers a wide range of standard cable assemblies, as well as custom solutions for high-speed data transmission. These are available as fully assembled versions or with open cable ends. Hybrid configurations that combine RMC® with FAKRA or HFM® connectors are also possible. Rosenberger's coaxial data connector portfolio addresses the growing need for powerful, flexible, and cost-effective connectivity solutions in the mobility and communications sectors of the automotive industry. The portfolio includes FAKRA as a proven standard, HFM® as a high-end, future-proof solution, and RMC® as an alternative.

Further information

Technical details, application notes, and downloads are available at: https://www.rosenberger.com/de/produkt/rmc-rosenberger-mini-coax/