Key Takeaways

- With high-quality sealing systems and automated mixing and dispensing technology, the international RAMPF Group enhances product quality and manufacturing efficiency in the lighting industry.

- Sealing systems based on polyurethane and silicone from RAMPF Advanced Polymers provide reliable, long-lasting protection for lighting components against dust, moisture, water, and cleaning agents.

- Mixing and dispensing systems from RAMPF Production Systems ensure maximum precision, fast cycle times, and outstanding flexibility when processing reactive sealing systems.

RAMPF Advanced Polymers offers lighting manufacturers a broad portfolio of sealing systems based on polyurethane (RAKU® PUR) and silicone (RAKU® SIL). The two-component reactive resins provide maximum and long-lasting protection against dust, moisture, water, and cleaning agents, ensuring reliable sealing up to IP 67.

They feature excellent resistance to UV radiation and high temperatures, making them suitable for both indoor and outdoor applications. Additional benefits include:

- Low water absorption

- Minimal assembly forces

- Short reaction times for fast component processing

- Stable and abrasion-resistant surface

- Exceptional aging resistance

- Certified to UL94 V0, UL50, UL50e

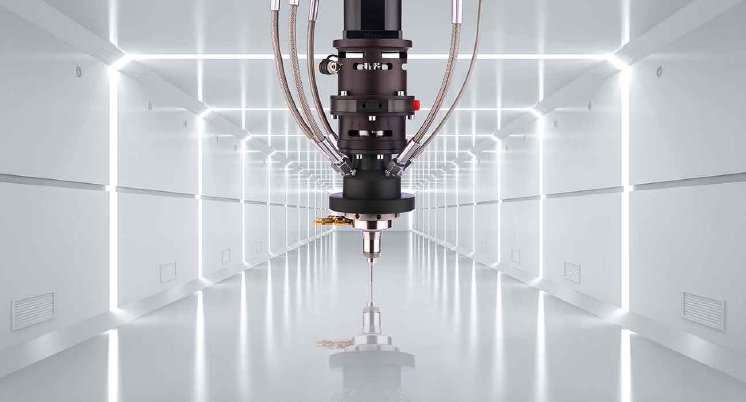

Automated Mixing & Dispensing Technology for Maximum Efficiency

Mixing and dispensing systems from RAMPF Production Systems stand for fast cycle times and maximum flexibility in lighting manufacturing. With a high degree of automation and autonomy, the systems ensure precise and reproducible application of single- and multi-component sealing systems – both as stand-alone solutions and integrated into existing production lines. Whether low- or high-viscosity foams, grooves, or flat profiles – RAMPF mixing and dispensing technology delivers ultra-precise results.

In series production, additional efficiency gains are achieved through RAMPF’s proprietary FlexSpeed technology. By synchronizing dispensing output with axis feed and using precise volumetric forced dispensing, cycle times are reduced by up to 50 percent. The dispensing robot reaches speeds of up to 40 m/min on straight paths and decelerates smoothly at corners and curves, ensuring consistently high sealing quality. Even with large-format lighting components such as linear luminaires, the geometry of the seal remains stable.

FlexSpeed also increases machine utilization while protecting mechanical components. Thanks to only brief periods of full load, wear is minimized. Speed-dependent dispensing protects mechanical parts and ensures sustainable efficiency improvements.