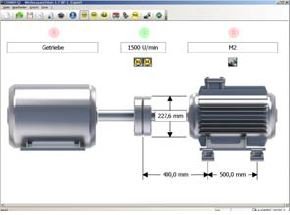

Given the high altitude of the location, it is necessary, especially in winter, to transport visitors to and from the Dachstein glacier with the cable car. A high availability of the lift system is therefore essential. For this reason, the main gear installed in the summit station was transported to the valley station by means of the auxiliary gear for overhaul during the four-week inspection shutdown that took place at the beginning of 2012. (See Fig. 1: View of the overall drive unit)

To assess the actual alignment condition prior to disassembly, it was necessary to measure both the alignment of the two 315 kW motors to the input shaft of the gear, as well as the drive wheel, which is connected to the drive shaft of the gear by means of a curved gear coupling. (Fig. 2: Gear with output shaft in foreground)

Since the time frame for the inspection was limited and the system had to resume operation for the Austrian "energy holidays", it was decided to conduct the measurements with a laser shaft alignment system. The fast and easy method of measuring with very good repeatability and the diverse report options were the factors that led to this decision. In the process of a system presentation, Volker Strack, an engineer at PRÜFTECHNIK Alignment Systems, was chosen to conduct this out of the ordinary task.

"Johannes Schlömmer, Deputy Manager of the Planai-Hochwurzen cable car company, coordinated the measurements and was immediately convinced by the simplicity of the system."

The Deputy Manager of the Planai-Hochwurzen cable car company, Johannes Schlömmer, was the responsible on-site employee. He coordinated the measurements and was immediately convinced by the simplicity of the system. With the measurement data, which he received in the form of a report, he was able to plan and implement any necessary corrections prior to reinstallation of the drive train.

First, the rotating axes of the two drive motors in relation to the gear input shaft were measured (Fig. 3). For this purpose, a chain-type bracket was attached to one half of the claw coupling and the laser mounted. On the other side, toward the flywheel mass, the sensor was mounted on the collar/flange of the claw coupling by means of a magnetic bracket. Since it was possible to uncouple the gear "by hand", the input shaft turned easily, making it possible to achieve a complete revolution for the continuous measurement mode. Using this mode, a rotation of as little as 60° is necessary.

Between measurements the sensor and laser had to be dismounted as the cable car was required to ferry the first group of artisans to their work site at the summit station.

At the end, the alignment of the drive wheel shaft to the gear output shaft was measured at the left and right of the curved gear coupling (Fig. 4).

It is noteworthy that the system had to operate at the slowest speed here, since the high torque needed for turning the drive shaft could not be achieved by hand. There were minor deviations between the extension and retraction, due to the change of load and direction.

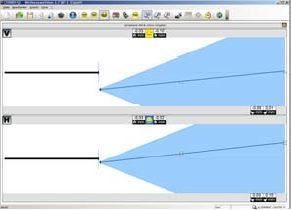

The measurement data was then analyzed using ALIGNMENT CENTER software, which showed that the system had operated with astonishingly good alignment during the past 43 years. The technicians, back in 1969 when this system was put into operation, had performed exemplary work using conventional measurement methods back then. (Figs. 5 + 6: Screens from the ALIGNMENT CENTER software)

Meanwhile, Planai-Hochwurzen-Bahnen GmbH has acquired a laser alignment system, which is currently being used successfully on the pumps of the artificial snow blower systems.

The Dachstein region:

The Dachstein southern face cable car in Ramsau/Dachstein was constructed in 1969. In 2003 it was acquired by Planai-Hochwurzen-Bahnen GmbH in Schladming, which also operates the Planai and Hochwurzen cable cars on the southern side of the Enn Valley. In 2003 and 2004 the drive system was converted from diesel motors to electric power, making it necessary to install a high voltage overhead power line up to the summit station. The valley station is reached via the Dachstein toll road. The cable tramway runs without a single support from the valley station at an elevation of 1,692 m to the "Hunerkogel" summit station at an elevation of 2,687 m, surmounting a difference in elevation of 1,000 m. The Dachstein southern face cable car also provides access to the glacier skiing area on the Dachstein glacier with the training centre for cross country skiing on the Schladming and Hallstätter glaciers. In 1997, UNESCO declared the Dachstein massif and the inner Salzkammergut and parts of the Ausseerland a world heritage site.