WMS for Resilient Intralogistics

The proLogistik Group offers a powerful, modular Warehouse Management System, pLG WMS, for holistic control and optimization of warehouse processes. The software provides transparency over inventories and workflows while intelligently managing operations. It can be flexibly tailored to individual requirements—from goods receipt and picking to shipping. Thanks to seamless integration with leading ERP systems and industry-specific features for 3PL, e-commerce, manufacturing, and retail, pLG WMS helps companies of all sizes improve efficiency, speed, and quality in warehouse operations. With real-time transparency, mobile access, and connections to automation technology, pLG WMS enables future-ready digitization of core logistics processes.

Flexible 3PL Module for Efficient Logistics Providers

The 3PL module is designed specifically for logistics service providers. It supports multiple tenants and locations simultaneously, enables rapid onboarding of new customers, and allows flexible, client-specific processes. The package also includes integrated interfaces, powerful billing with customizable terms, a customer portal, and BI-driven analytics. Expandable microservices such as dock and yard management complete the solution. This equips logistics providers to meet diverse customer demands, high service and speed expectations, and complex regulatory requirements.

End-to-End Transport Management for Maximum Efficiency

With its cloud-native Transport Management System, pLG TMS, the proLogistik Group provides a future-proof solution for comprehensive control and optimization of transport processes. The platform combines integrated modules—including route and tour planning, yard management, automated order processing, and a customer portal—into a single application, ensuring full transparency from planning to delivery. An integrated shipping system allows seamless connections to over 350 carriers and freight providers. Automated features such as invoice verification help companies reduce manual effort, accelerate processes, and sustainably improve service quality and cost-efficiency.

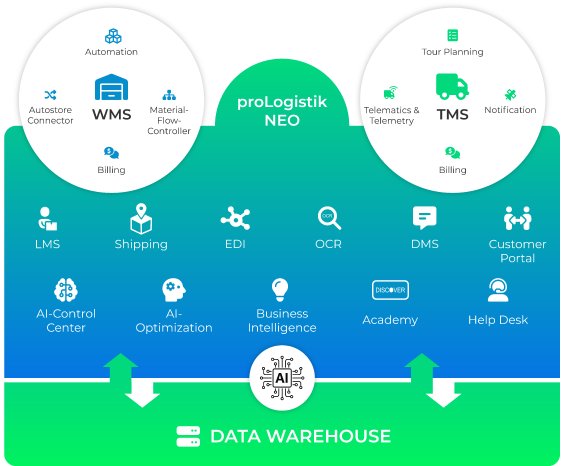

One Platform for All Supply Chain Solutions

The modular, data-driven proLogistik NEO platform unites WMS, TMS, Business Intelligence, and the AI control hub, the “AI Control Center,” in a single interface. proLogistik NEO offers features such as single sign-on, role-based access, and centralized master data management. This reduces integration efforts, increases transparency, and accelerates decision-making across the entire supply chain. A centralized data warehouse consolidates data from internal solutions and third-party systems, creating a unified data foundation.

proLogistik NEO addresses a key challenge: fragmented legacy systems that require high integration and maintenance efforts. “proLogistik NEO brings together warehouse, transport, analytics, and our AI control hub in a single interface—reducing complexity and speeding up decisions,” emphasizes Jörg Sänger, CEO of proLogistik Group.

Smart Control Hub “AI Control Center” Simplifies Warehouse Operations

The AI Control Center combines the power of artificial intelligence with a BI tool and offers customers two specialized agents: The AI Control Agent answers questions directly in the system via chat—no need to go through support or documentation. Queries like “How many open goods receipt orders do I currently have?” are answered instantly. The agent also provides relevant KPIs for warehouse operations, issues early warnings for predefined deviations, and offers context-sensitive recommendations for logistics processes. This enables significant time and cost savings. The AI Optimizer simulates scenarios using a “digital twin” of the warehouse and evaluates alternatives for proactive process management. Based on these simulations, storage locations are optimized, orders are grouped efficiently, and pickers’ routes are intelligently managed.

Efficient Management of the Largest Cost Factor in Warehousing

In intralogistics, labor represents a major cost factor, accounting for roughly two-thirds of total warehouse expenses. By comparison, costs for buildings, infrastructure, and other operational areas are lower. Against this backdrop, optimal planning and management of human resources are critical for warehouse performance.

This is where the pLG LMS (Labour Management System) comes in. The data-driven solution consolidates all relevant warehouse information in a single system. Performance, process, and personnel data are linked to create a unified view, enabling forward-looking planning and targeted management rather than purely retrospective reporting. A central monitoring dashboard provides a clear overview of key performance indicators across one or multiple sites.

The system makes a significant contribution to greater transparency, improved planning, and sustainable efficiency in intralogistics.