The innovative “ProfilControl 5-Medictube” inspection system is the first system to inspect inline the quality of medical tubing already during the production process and over the complete tube length. Up to now, such tubes could only be inspected by random checks.

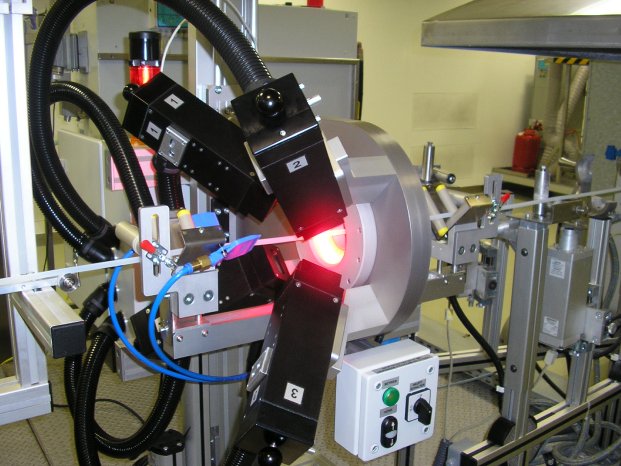

ProfilControl 5-Medictube can be used to inspect tubing made of PVC, PE, PUR or rubber and used in medicine, for example, for cardiac catheterization or dialysis. Due to its compact design – it requires an installation length of only 250 mm – ProfilControl 5-Medictube can be easily integrated in existing production lines. The system is suitable for use under clean room conditions.

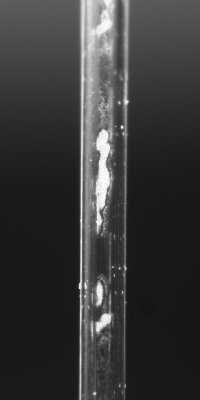

Especially for medical tubing the homogeneity of the tube material plays a decisive role: If, for example in transparent dialysis tubes, inhomogeneities are mistaken as blood or other contaminations or an inclusion in the tube wall is misinterpreted as an air bubble, this can cause irritation or lead to false conclusions.

Pixargus PC 5-Medictube detects such defects - for example holes, fissures, foreign particles or inclusions in the tubing material – already during the production process. The operating staff can immediately take corrective action and sort out the defective material. At the same time it helps to avoid such defects in the future.

Besides the fact that the outside diameters of the tubing are often very small, the semi-transparency of the product surfaces poses another challenge to inspection system designers and was one reason why automatic inspection of these materials was not possible in the past. Also material-inherent reflexions of the lustrous tube surfaces pose a difficult-to-solve problem for optical inspection systems. Pixargus has now succeeded in combining light and camera technology in a sophisticated design that despite these difficulties makes material defects visible.

Björn Lindner, Managing Director of Pixargus, sees great advantages for both manufacturers and users. “Especially in medicine 100 percent inspection is a must. At production speeds of 50 m/min and above the human eye is unable to detect extremely small irregularities, above all on a transparent material. Also so-called node monitoring devices, which used to be employed in the past, only measure the outside diameter in two axes. Our system, on the other hand, inspects every individual centimetre of the complete tube. This ensures that only material of perfect quality is delivered to the customer. But the system also helps manufacturers to significantly reduce their production costs.”