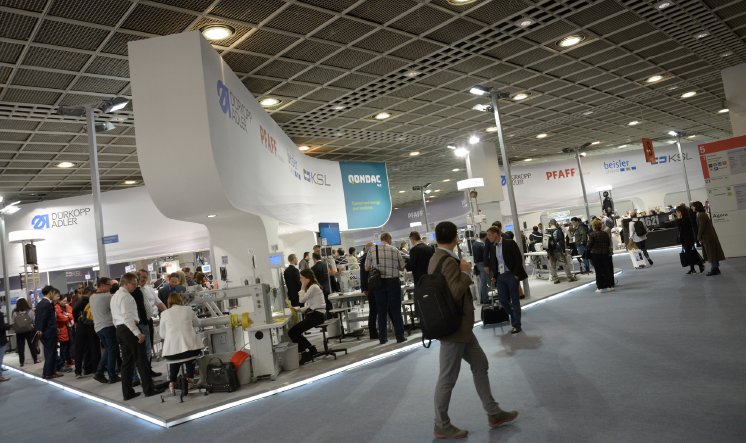

Using the motto „Together for you“, companies Dürkopp Adler AG and PFAFF Industriesysteme und Maschinen GmbH along with Beisler and KSL presented the latest high-tech machines to „join“ textile materials and leather at a joined booth covering 1,000 sqm. On one hand, more than 100 exhibits showed real solutions for specific applications; on the other hand the group demonstrated that it is well-positioned for the industry’s future topics industry 4.0 and robotic technology. Digitized sewing production becomes reality with QONDAC 4.0. QONDAC is an industry 4.0-network-solution for up to 1,500 sewing machines. QONDAC permits real-time identification of potential for optimization, supports the individualization and saves costs by remote maintenance. QONDAC 4.0 has been awarded the TEXPROCESS INNOVATION AWARD 2017 in the category "New Process".

The area of robotics and automation technology was another focus at the trade show. The PFAFF 3538, a pocket hemming unit with a new fully-automated pocket-loading station, was shown. Once the magazine is stocked (with up to 500 pocket cuts), the machine works completely without an operator. An output of approx. 16,500 pockets over 8 hours is possible. The automat drew large crowds. Along with other jeans machines, it was integrated into a “live” manufacturing demonstration of jeans-pocket production.

The two robotic case studies by PFAFF/KSL demonstrated how one combines robotics with a specific application. In one system a handling robot realized a fully automated bobbin change (on a PFAFF Plusline 2481) by accessing an octuple changing rack. In addition, the robot guided the part to be sewn past the sewing machine and thus completed the operation „stitching the dress shirt collar” fully automatic. At another system a handling robot fed two PFAFF-ultrasonic welding machines with textile parts. One welding head trimmed the part using ultrasound whilst the other welding head added a decorative weld seam.

In hall 6.0 the „Digital Textile Micro Factory“ provided a live performance of an entire textile manufacturing chain. PFAFF INDUSTRIAL und Dürkopp Adler were responsible for the „joining“-process and each provided some machines and demo staff for this successful presentation.

In September 2017 Dürkopp Adler AG and PFAFF Industriesysteme und Maschinen GmbH along with Beisler and KSL want to make a similarly impressive appearance at the CISMA in Shanghai.