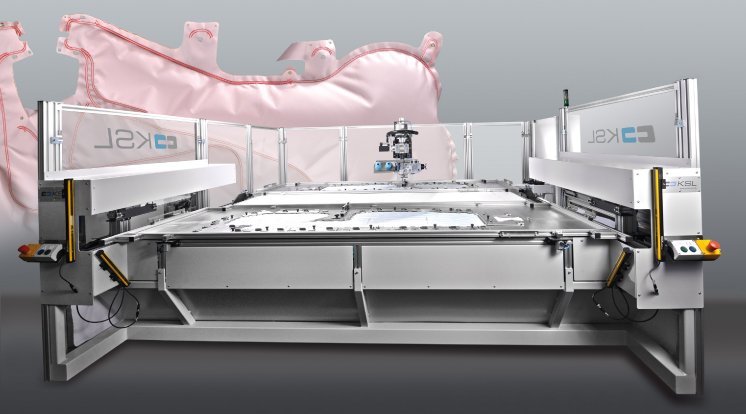

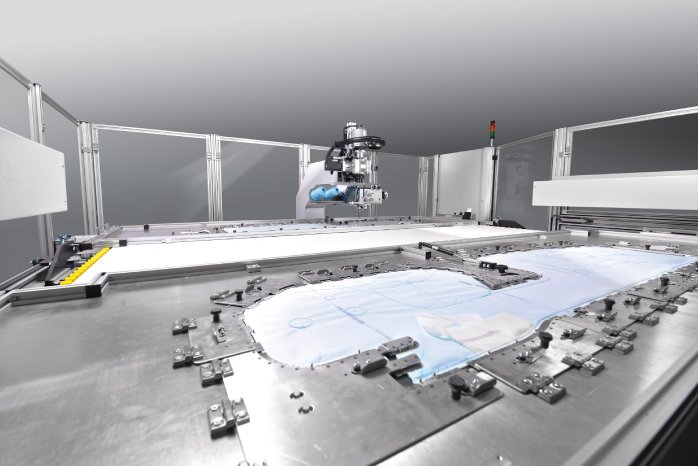

The KL 110, a freely programmable CNC-sewing unit featuring a turning head, is offered either in a one- or two-needle version and generates up to 2,800 stitches per minute. Due to the tangential orientation of the sewing head into random sewing directions, complex seams may be produced in top quality as back stitch or chain stitch. At the TEXPROCESS 2017 in Frankfurt, the machine was presented with a barcode-scanner system to record data in multiple applications and immediate analysis via the HMI-operator panel. The turning head-technology is also used for applications beyond airbags resp. car seats e. g. for sophisticated decorative stitching operations on a KL 311 (virtually identical in construction to the KL110) at a European manufacturer of luxury goods. Likewise, the door panels and seats of the new model of a British luxury car manufacturer are sewn using a KL 311 with turning head.

KL 110 Headbag

Process reliability for up to 3,500 x 1,000 mm

The KL 110, a freely programmable CNC-sewing unit featuring a turning head, is offered either in a one- or two-needle version and generates up to 2,800 stitches per minute. Due to the tangential orientation of the sewing head into random sewing directions, complex seams may be produced in top quality as back stitch or chain stitch. At the TEXPROCESS 2017 in Frankfurt, the machine was presented with a barcode-scanner system to record data in multiple applications and immediate analysis via the HMI-operator panel. The turning head-technology is also used for applications beyond airbags resp. car seats e. g. for sophisticated decorative stitching operations on a KL 311 (virtually identical in construction to the KL110) at a European manufacturer of luxury goods. Likewise, the door panels and seats of the new model of a British luxury car manufacturer are sewn using a KL 311 with turning head.