据NUM瑞士总部的NUMROTO应用经理Jörg Federer说:"NUMROTO是我们的旗舰产品。自该软件于1987年首次发布以来,其开发一直围绕着一个核心原则,即要实现全面的刀具磨削解决方案,必须对整个工艺链进行分析和优化。新的数字显微镜将我们的表面分析能力扩展到了亚微米级,为工艺技术和刀具生产质量提供了宝贵的反馈"。

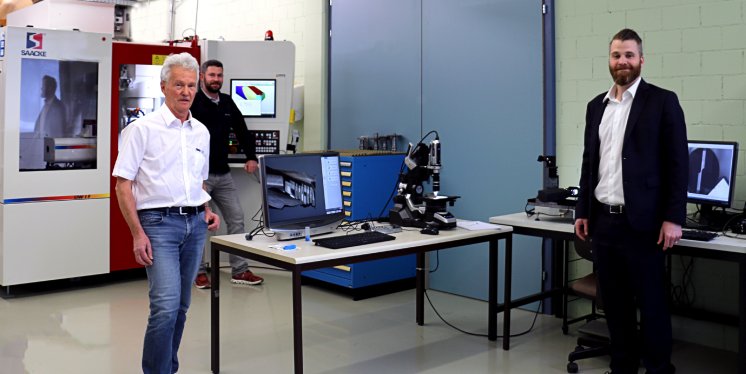

作为高端数控技术的领导者,NUM拥有广泛的研究和开发设施。这些设施涵盖了数控系统和驱动器的硬件和软件组件,以及各种类型的电机设计。NUMROTO技术中心是这些设施的延伸,提供内部产品开发专业知识和客户可获得的应用支持服务。

由于高性能的数控平台,如NUM的Flexium+ 系统,今天的许多机床都能够产生超强的效果。NUMROTO软件可以非常精确地计算路径,理论上应该总是产生微米级精度的刀具。然而,一些因素可能会阻止这种精度反映在磨削工具上。

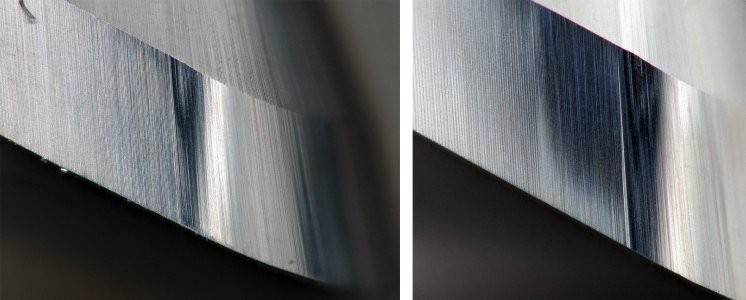

磨床误差的主要原因是机械极限和磨损,而这些误差通常是可以纠正的。动态极限的影响通常表现在几何元素之间的过渡上,如球头半径和半径铣刀的圆柱体之间。这个关键区域通常在100毫秒内穿越--在此期间,旋转轴停止,旋转轴迅速加速--这意味着次优的驱动设置可能导致磨合。通过使用数字显微镜分析刀具表面的任何可见痕迹,就有可能确定对驱动设置的必要修正。

刀具磨削误差的另一个常见来源是,当砂轮不能完全真实地运行或不能干净地修整。这可能会在刀具的浮雕角上产生规则的沟槽,特别是在浮雕角之间的过渡处。肉眼看不到,甚至用放大镜也看不到,这些沟槽是由砂轮在每一次旋转过程中与工件的摩擦造成的。数字显微镜的高分辨力有助于快速检查砂轮的状况和动态性能。

NUMROTO技术中心的专业知识和资源可供客户以及NUM的研发团队使用。该中心对特殊工具进行可行性研究,并提供NUMROTO客户培训。