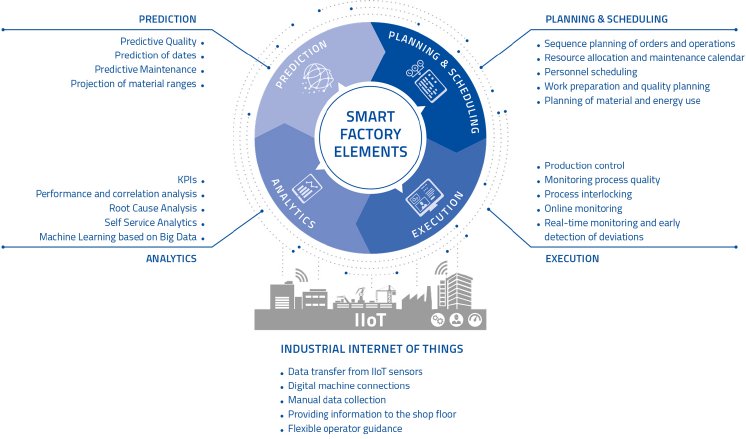

The Planning & Scheduling element symbolizes the planning capability of production in terms of resources, time and maintenance. The specifications can be efficiently implemented and documented. The Execution element represents this. Based on the collected data, analyses can be created to check whether the figures are met and to identify potentials for optimization (Analytics). For example, the analyses are used to make predictions about how likely a malfunction is or when maintenance is necessary again (prediction). The Industrial Internet of Things (IIoT) collects data and provides these.

The five elements of MPDV's Smart Factory Elements model help to implement the plan of a Smart Factory in a specific way. MPDV's model makes a significant contribution to the successful transformation of manufacturing companies into Smart Factories.

Learn more about MPDV's Smart Factory Elements model in this video: http://mpdv.info/prsfevideo