Hall 4 / Booth C25

- New Feature enables Automated Process Analysis

- Integration of Tailored Solutions including Supplier Selection

- Leveraging Insights from 500,000 hours of Data

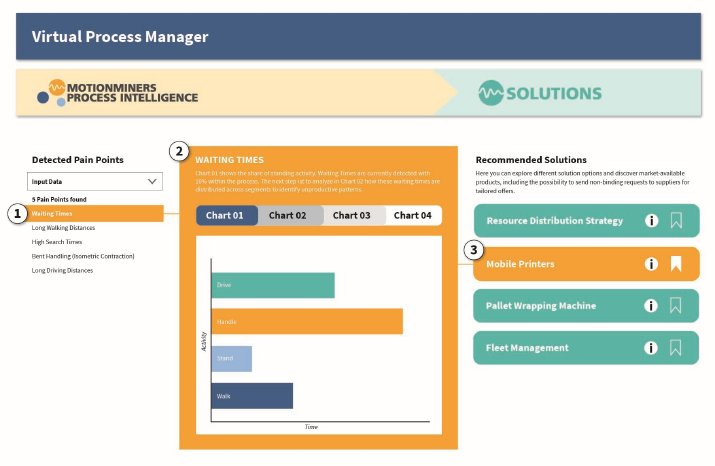

Intralogistics optimizer MotionMiners is expanding its analysis platform MotionMiners PROCESS INTELLIGENCE with a new “Virtual Process Manager.” This innovative feature automatically identifies process inefficiencies based on captured movement and activity data and matches them with suitable solution approaches, including potential vendors.

“The KPI analysis, which previously required deep process expertise and manual interpretation, is now handled directly by our analysis dashboard,” explains MotionMiners COO Sascha Kaczmarek. A prototype will be showcased at LogiMAT in Stuttgart (March 24–26, 2026, Hall 4, Booth C25).

The foundation of this new tool is more than 500,000 hours of process data collected over eight years of Motion-Mining projects. In purely mathematical terms, this represents a knowledge base equivalent to three centuries, anonymized and standardized for automated analysis.

From KPIs to Actionable Insights – Without Manual Interpretation

“Our goal was to transform raw movement and activity data into actionable insights – not just KPIs, but identified problem areas and corresponding solution strategies,” says Kaczmarek. The tool will be able to distinguish a wide range of inefficiency types, such as long walking distances, excessive search or waiting times, and ergonomically unfavorable tasks like frequent bending.

Until now, MotionMiners PROCESS INTELLIGENCE automatically converted captured data into over 100 process KPIs. However, interpreting these KPIs – determining the underlying problem and potential solutions – was left to the user. “This manual step is now eliminated,” Kaczmarek emphasizes. “Instead of relying on a process engineer’s expertise, the software will automatically detect inefficiencies and suggest optimization options, including supplier recommendations,” he adds.

Seamless Integration with MotionMiners SOLUTIONS

This holistic approach is made possible through integration with MotionMiners SOLUTIONS, a web-based platform launched in 2023 that now includes over 420 products and services. “With this new feature, we merge our analytics and solution worlds into a seamless, fast process optimization experience – requiring no prior expertise,” Kaczmarek concludes.

The free-to-use SOLUTIONS platform has been continuously enhanced over the past three years. Through guided search – supported by an integrated Large Language Model – users can describe logistics challenges in everyday language. The platform translates these inputs into relevant problem areas and suggests comparable solutions from multiple providers.

A Milestone Toward Automated Process Optimization

By combining the new analytics tool with the solution database, MotionMiners takes another step toward fully automated process optimization. “We’ve created a continuous triad: data collection, automated problem detection, and concrete solution recommendations,” summarizes Kaczmarek.

The foundations of the Virtual Process Manager are being developed within the SENSOMAI project, funded by the Federal Ministry of Research, Technology and Space. A beta phase with selected customers will begin later this year. Future development aims to continuously expand the knowledge base from Motion-Mining projects and make it accessible to the industry.