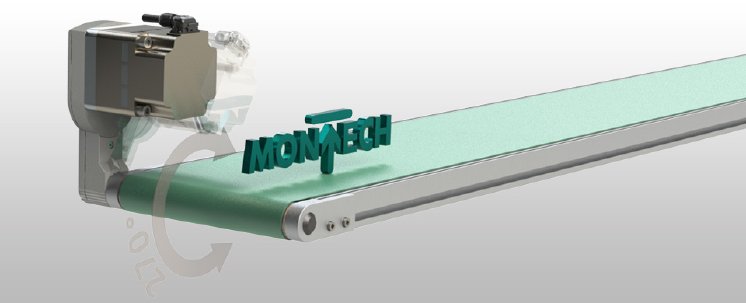

Belt conveyor with swiveling drive

Montech offers solutions for clean and energy-efficient processes. The company specializes in the industrialization and standardization of state-of-the-art, unusual belt conveyors, transfer systems, and innovative aluminum framing systems. Its TB30 belt conveyor is characterized by a swiveling head drive. Because it is located above the belt conveyor, it does not come into contact with oil or cooling emulsion, so it avoids soiling the motor. In addition, this arrangement also saves space. The freely selectable angle range of 0 to 270 degrees allows the swiveling head drive to be positioned according to individual requirements. The brushless DC motor provides variable speed and offers a high degree of protection as well as optimized efficiency. The control is handled manually or digitally via I/Os with an external controller. Depending on the degree of protection required, the external controller can either be attached directly to the belt conveyor or placed in a separate control cabinet.

Stainless steel oil collection pan

As further protection against dirt in the working area, Montech offers an integrated oil collection pan made of stainless steel. If necessary, it can be installed in the floor stands and thus positioned directly below the TB30 belt conveyor. It integrates optimally, takes up little space, and collects the dripping oil safely. The hole in the pan bottom lets the oil drain directly. The hole is milled customer-specifically for an optimized, clean work process. Rollers are also available for the substructure on request. This makes the entire conveyor unit mobile and easily accessible. The ability to roll the unit away easily is, for example, an advantage for maintenance work or when it is to be used on several or different machines; its universal characteristics make this possible.