1973 - Start for spark extinguishing technology

In the early 70s, new emission protection laws coming into force increasingly required the use of extraction and dust removal systems to reduce the emission of pollutants.

Defective or blunt/worn down machine components, as well as the entry of foreign substances, however, led to dangerous flying sparks in the extraction and dust removal systems and increased the risk of severe fires and explosions in the downstream filters. Therefore a special fire protection solution not yet available on the market needed to be developed to satisfy these requirements.

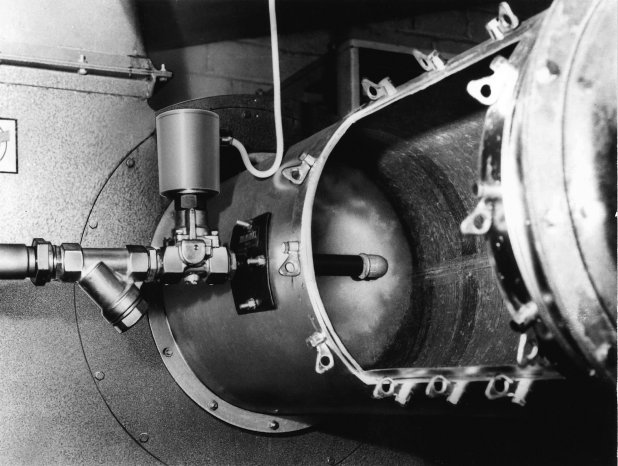

Minimax thereupon designed the first FEZ 2000-type fire detection and extinguishing system with three monitoring areas. The innovative technology made it possible to recognise and fight the sources of ignition in closed conveyor lines within split seconds, even during the ongoing operation of the extraction or conveyor systems. Special infrared FUX1000 and FUX1001 spark detectors were constructed to operate with the FEZ 2000 control panel, the SD 50 came into use as extinguishing nozzles. As soon as a spark was detected, the open brass nozzle released water and sprayed it in the direction of the material transport to extinguish the sparks. For the optimum and complete coverage of the conveyer channel crosssection the nozzle was centrally situated in the conveyor line.

Mid 70s to 80s with intelligent further developments

To be able to additionally cover other peripheral and production areas at risk of fire at the same time as the material conveyance and transport areas Minimax presented the first combined spark and fire detection panel, the FMZ 2001. For the first time this made it possible to operate and monitor up to ten extinguishing areas for the combined use in purely building protection as well as during industrial processes. The detector range was expanded with the FUX 1100, which could be used in additional areas and detect even more reliably thanks to improved components.

After just a few years following the introduction of the FMZ 2001, another innovative step in control panel technology was achieved: In the early 80s the new development of the FMZ 3000 was already capable of monitoring up to 40 areas and moreover had a spark counting function to control the machine reaction or shut-down via the extinguishing system's relay outputs. In addition the FMZ 3000 could also recognise and monitor faults in its own system, such as wire breakage or short circuits. The smaller FLE 3000 was especially developed for customers, for whose applications one system with only one area is sufficient.

In the late 70s the industrially manufactured spark detector series FUX3000 and FUX3001 were designed as a robust IP65 model, which were able to withstand the generally tough environmental conditions of the woodworking industry without difficulty and were thus even more reliable. To be able to also monitor high temperature channels, such as dryer tubes, the detector housing of the highly sensitive FUX3001 L1 spark detector with temperaturesensitive components, such as sensors and electronics, was thermally decoupled from the optic window via optical fibre. Another detector during this period with a special function was the FUX3001 DL. It used a different sensor and was preferably used in processing areas, which could be influenced by outside light sources or during which the process needs a different detection spectrum. For a spark detector to function reliably the sensor had to be able to receive the IR radiation of a spark or hot particle through the optical window at all times. In environments, such as in the woodworking industry, however, the optic window of the detector can be contaminated by material deposits and thereby "blinded". From the 80s, the FTX3000 spark test detector provided additional operational security, which tests a spark detector's response using an external spark test light. It executed a visibility and function test of the spark detector under real conditions and a targeted report in the event of malfunctions.

In addition to the new panel and detector technology this decade also brought forth the SD50-T and SD50-K extinguishing nozzles. These were self-closing nozzles, which open under increasing water pressure and re-close after the extinguishing process via spring tension. Hence, in contrast to open nozzles, it is not possible fore conveyed materials to enter the nozzles and clog them. The SD50-K nozzle is constructed so that it can also be used in counter-flow extinguishing and sprays in the direction opposite to the materials flow. This process is patent protected.

The 90s - everything gets easier

Minimax brought the microprocessor-driven, combined fire detection and extinguishing panel FMZ 4100 onto the market. It fulfilled the requirements for an increasingly individually configurable spark detection technology and with its additional integrated LKM leakage and flow rate detector also made it possible to recognise pipe breakage or nozzle clogging early on. As soon as anomalies are recognised in the water flow, the panel emits a signal and the error can be precisely localised and accurately rectified for the area. An enormous plus factor in maintaining a system.

The newly developed FUX3001 ELM detector likewise contributed to the simplified application. Until then a laborious mount was needed for the detector assembly. The FUX3001 ELM was the realisation of the single hole assembly. Only one screw connection is sufficient. The detector can thus be significantly more easily installed, maintained and cleaned.

The FUX4000 UEWA spark detector, a modification of the FUX3200 L1 UEWA, was developed for application in systems with the most stringent security requirements: This has an automatic visibility monitoring of the optics against impurities and thus united the functions of the FUX-series detectors and the FTX3000 spark test detector in one. The process - how the detector continuously monitors the visibility and tests its electronics for correct functioning - is patent protected.

Although the SD 50-T and SD 50-K nozzles represented a major developmental milestone in nozzle technology, one weakness remained: For total-surface coverage the nozzles were centrally placed in the piping around the channel cross-section and were hence exposed to wear and tear from the materials constantly flying by. From the end of the 90s the introduction of the self-closing F180 flat jet nozzle had relegated this to the past. This nozzle is attached flush to the side wall of the conveyor channel via a single hole assembly. As the fanshaped spray has a spray angle of 180º and immediately builds a homogenous water curtain, this patented extinguishing nozzle can completely protect both round as well as square cross-section contours. In addition the nozzle spray is powerful enough to even penetrate a material flow with a greater density.

2000 to today - maximum monitoring, speed and flexibility

Minimax has continuously worked on optimising fire detection, valve and nozzle technology, in order to shorten reaction times and hence also enable a shorter distance between detector and nozzle. This interplay of rapid technologies achieves even greater security with maximum flexibility at the same time.

The FMZ 5000 stands as a perfect example for the times of maximum flexibility: The fully modular assembly of the FMZ 5000 fire detection and extinguishing control panel has a graphically freely-programmable control, whereby up to 32 centres and parallel display fields can be redundantly combined with one another into one ring-shaped network. The control panel monitors all spark detectors including their function monitoring, flow alarms, shut-down devices, pressure boosting systems, trace heating, extinguishing valves and spark test detector equipment. One of the three spark counters, which is available for each spark detector line, offers the function of averaging over a freely definable period. Each spark detection and the start and end times of the extinguishing process are precisely recorded to the millisecond in a memory with a capacity for over 50,000 entries.

The optional "Reflex Module" for the FMZ 5000 offers a combined fire detection and spark extinguishing function for both pneumatic conveyor systems and extraction systems. Spark detection and the extinguishing process are "reflexive". The "Web Module" enables data access via the Internet and web browser for remote diagnosis and/or remote control and thus reduces servicing and maintenance expenses.

The WinGuard security information management system from Minimax represents a further development in increasing transparency and (spatial) flexibility: It is a clearly arranged and user-friendly system for visualising and operating security and fire detection systems. The system-wide, uniform operating concept designs for users the complex contexts - as are particularly the case in this area - in a clear and easily understandable manner. The current status of monitoring points can be displayed in graphs, as text reporting or animated elements.

WinGuard thus enables a monitoring, which is particularly important in spacious and complex building structures, as are common in industrial plants. The fire detection and control system signals, such as alarms or events, activate the corresponding reporting and trigger predefined responses. It can also notify people specified in advance via SMS, email or fax.

Customers also have additional flexibility due to the expansion of the entire product range of spark detectors and extinguishing technology for use in ex-dust zones. These products have been specially developed or modified for these areas and meet the requirements of the European Directive ATEX 94/9EC.

40 years of successful spark extinguishing

Since the first successful commissioning of a spark extinguishing system in the year 1973, the Minimax brand has not only stood for the field of spark extinguishing. Minimax GmbH &

Co. KG is also a VdS-certified company for the planning and installation of fire protection systems in all areas of the woodworking industry: Regardless of whether they are combined pump, sprinkler, spray water, foam, spark and gas extinguishing systems or fire detection systems - Minimax stands for comprehensive fire protection solutions under one roof.

Minimax developments have various international certifications, such as VdS or FM, and are for example also certified in countries, such as Russia. The path the company has taken also promises all-in-one comprehensive fire protection solutions for wood plants for decades to come: From the development of innovative systems and product components to their manufacture to effectiveness testing under real conditions.