One indicator for the booming agricultural economy in Great Britain and Ireland is the rising number of students in the universities. Parallel to the successful graduations is the increasing requirement for high quality equipment which is up to the raw everyday life in the fields. Agriweld Ltd. has been in business as a manufacturer of agricultural machines and equipment since 1992. To be able to continue to meet the demand at a high level the directors, Dean and Dawn Foster, were considering acquiring a used laser system: “We thought that with a second-hand unit we could save some money and still be able to produce more efficiently. However, we found out about the new MetalMaster 2.0 from Messer Cutting Systems through the launch campaign and were already impressed by its features on paper – not least the price!”

When “less” convinces: Price and space required

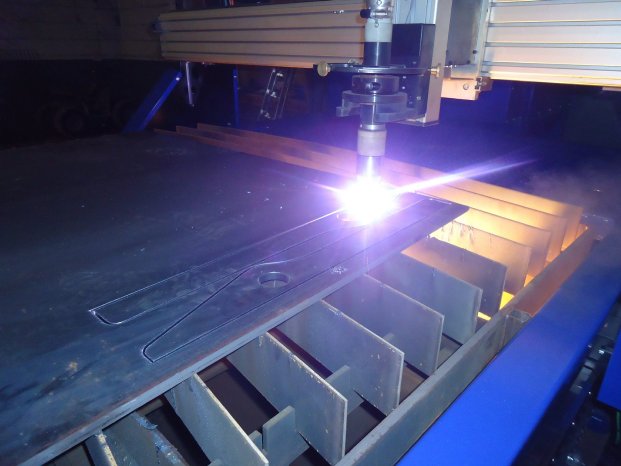

So Agriweld decided for the smallest version of the MetalMaster 2.0 as a new purchase, as it gave full performance on about 30 square metres area, to cut plates up to 3,0 x 1,5 m with plasma or optionally the oxyfuel process. The machine is, however, not just compact but also quickly installed and ready for operation.

Already on the first day, the MetalMaster 2.0 improved the efficiency with respect to speed and precision. “That reduced our labour costs which had, until then, been required for finishing operations”, said Dean Foster. “This is an enormous advantage, especially with small batch quantities or one-off rush jobs, as we can give the parts to the customer without further operations like grinding or drilling.” Thanks to the Messer Hole Technology the machine cuts holes as drilled.

Triple click to start

And the MetalMaster 2.0 is ready to cut at the flick of the wrist. Dean Foster on this: “Fascinating, how easily the machine can be operated with the Touchscreen of the Global Control 2.0. From loading the part program to the first cut you only need three clicks – and you are ready to go!” The basis of the control is the modern, Windows® based operating system: with the Touchscreen all parameters can be loaded or entered in the shortest time. Whether it is gas pressure or plasma current, even the wear on the consumables is displayed on the TFT monitor.

Precision and speed unified

The MetalMaster 2.0 combines the oxyfuel and plasma cutting processes with which a wide range of materials and cutting tasks can be covered. The torch moves over the plate at speeds of up to 35 metres per minute. In combination with the fast torch lifter SL100 – barely half a second is required for the full stroke – unproductive time is minimised. Dean Foster: “The pace at which the MetalMaster moves is impressive. To this are added the optimise plasma process which can save up to five seconds per start. For us this means that we can cut faster and more efficiently and deliver even more quickly!”

In addition the precision guiding system ensures the highest accuracy even over long production times. “Whilst we used to have to choose between speed and quality, now with the MetalMaster 2.0 we have both at once. The cut edge precision is especially unbelievable”, stresses Dean Foster.

The fume extraction integrated into the table with the fan /filter system meets all environmental technical requirements, of course, to avoid dust and fumes. Specially designed slag containers simplify table cleaning significantly.

Attractive in both price and performance

Dawn Foster, Managing Director and Sales at Agriweld Ltd. is totally satisfied with their decision for the MetalMaster: “The cutting machine with the new plasma technology opens almost unlimited opportunities for us. With such power in the production we can also regard even the most demanding orders in future without concern.”